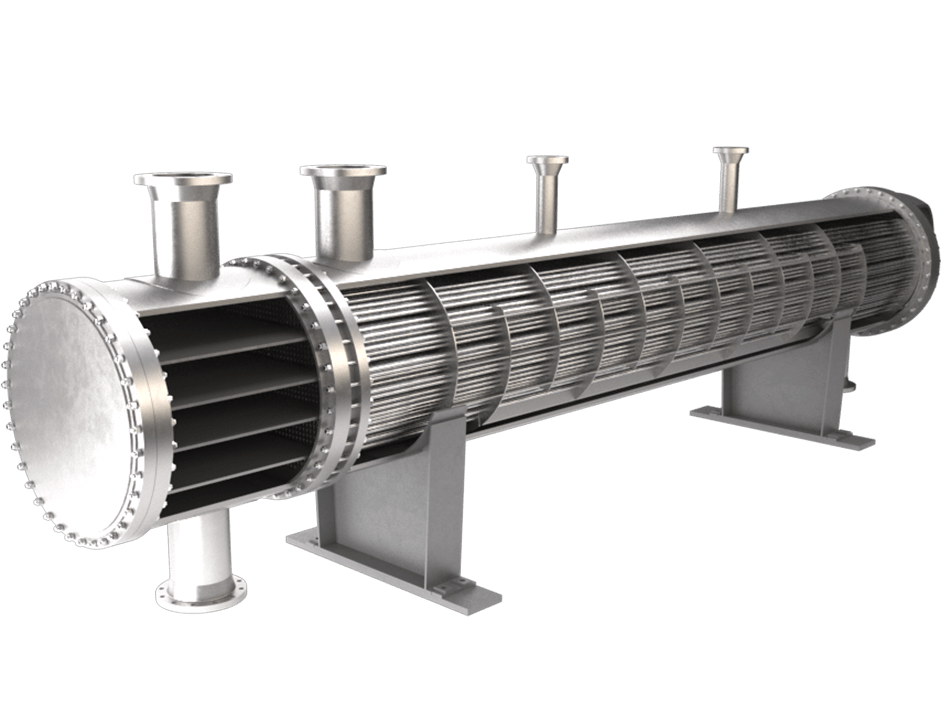

THE- Model High-Efficiency Shell & Tube Heat Exchanger

THE Model shell & tube heat exchangers are high-capacity, efficient, and durable heat transfer solutions designed for industrial facilities and commercial applications. Their compact design ensures maximum energy efficiency, making them a reliable choice for both industrial and domestic applications.

🔹 Capacity Range: 34 kW – 8,093 kW

🔹 Maximum Operating Pressure: 6 bar (0.6 MPa)

🔹 Maximum Operating Temperature: 90°C

🔹 Heating-Heated Fluid: Steam – Water

⭐ For special orders or project-specific requirements, shell & tube heat exchangers can be manufactured for heat transfer applications involving liquid-liquid, liquid-gas, gas-liquid, and gas-gas processes..

INSUZ THE Model Shell & Tube Heat Exchanger Capacity Table

Selection Table for Steam-to-Water Heat Transfer

The following selection table has been prepared for Insuz THE model shell & tube heat exchangers operating at various pressures and capacities for steam-to-water heat transfer. Please review the table to determine the most suitable model for your needs.

⚠️Custom manufacturing options are available for special projects and specific technical requirements.

🚀To help us provide the best solution for you, please fill out the inquiry form and contact us.

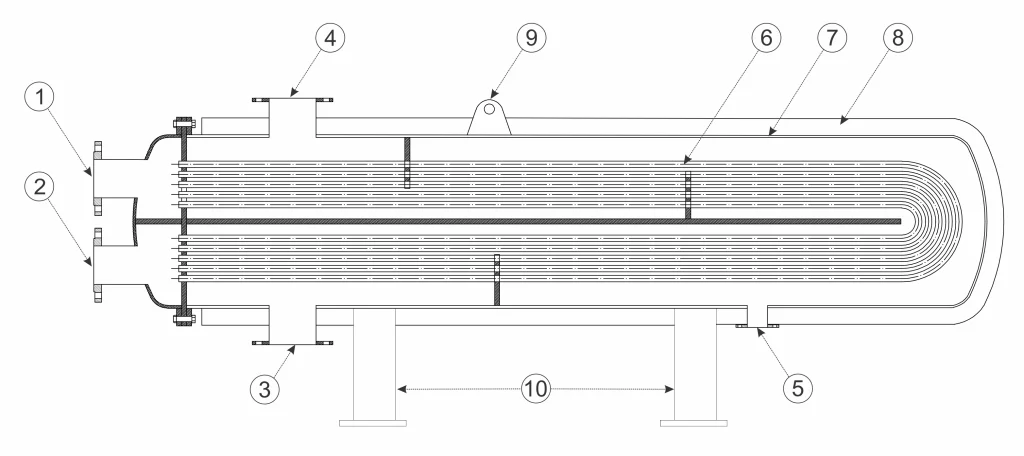

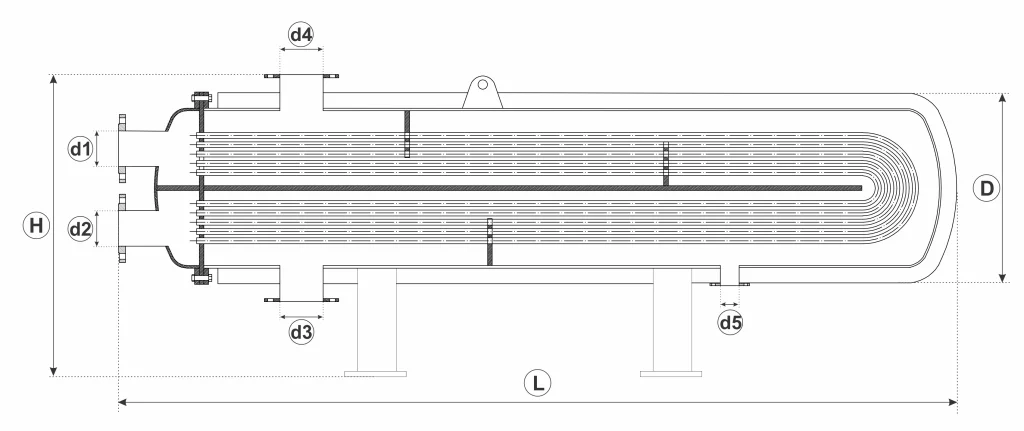

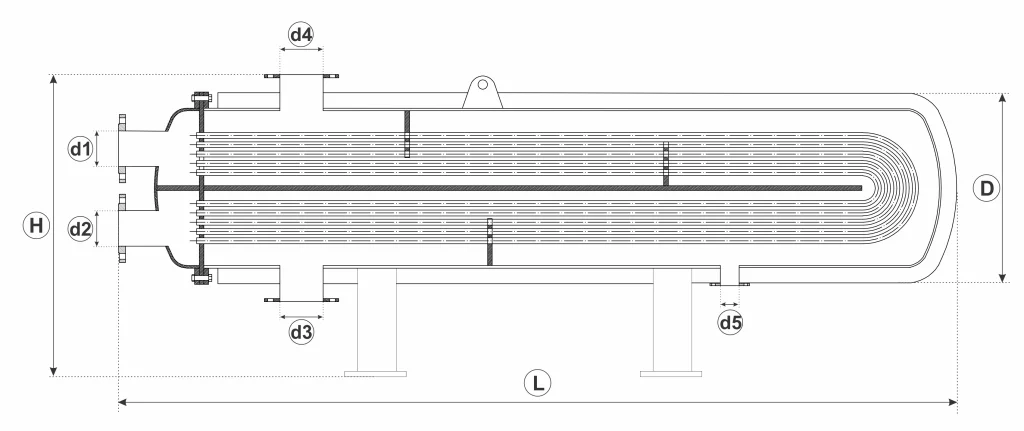

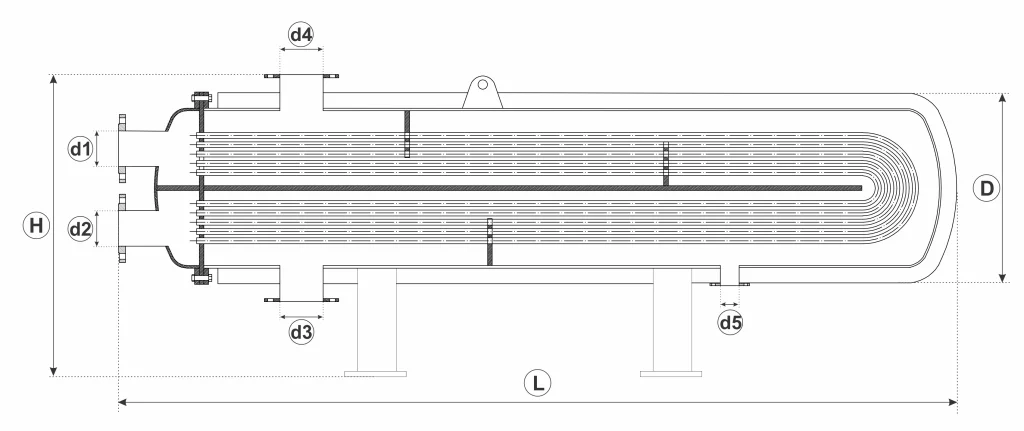

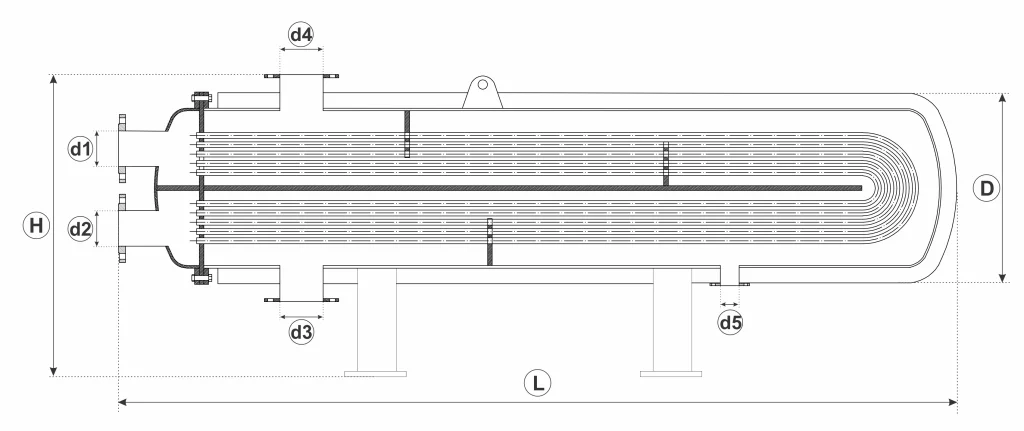

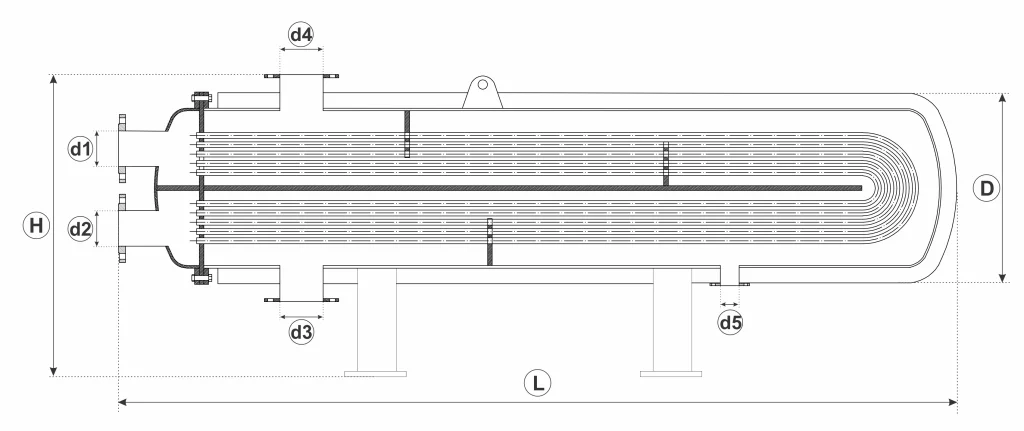

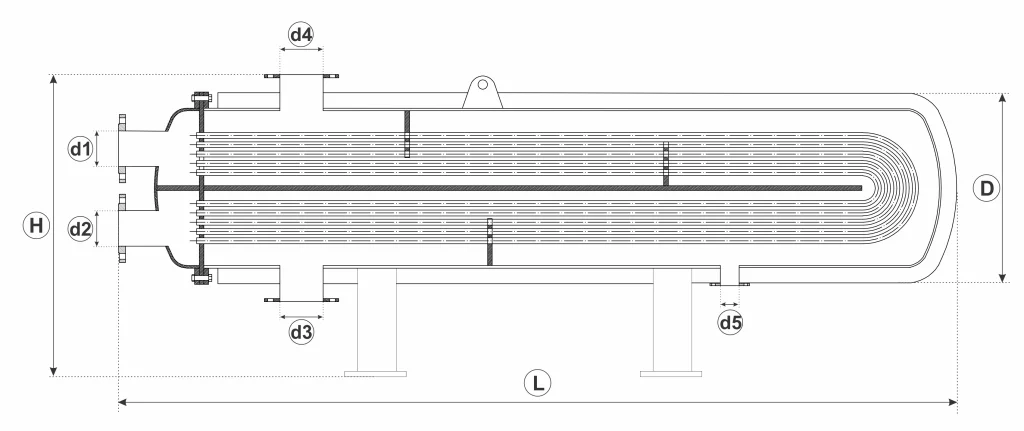

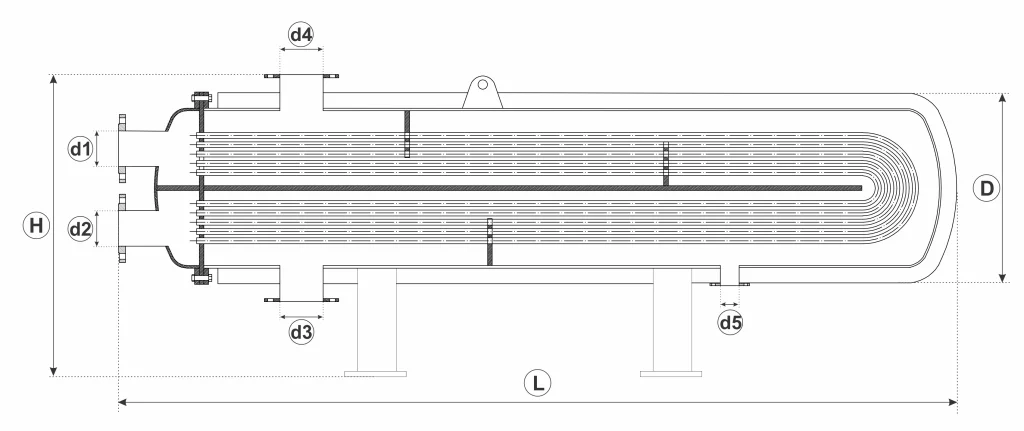

1- Steam Inlet, 2- Condensate Outlet, 3- Water Inlet, 4- Water Outlet, 5- Drain, 6- Coil, 7- Shell, 8- Insulation, 9- Lifting Lug, 10- Legs.

⚠️Model Kesit ve Bağlantı Ölçüleri tablosu yalnızca masaüstü cihazlarda görüntülenebilir. Mobil cihazlarda desteklenmemektedir.

Capacity Table Based on Operating Pressure

| Model | 90/70 sıcak suya göre ısı yükleri kW/s | ||||||

|---|---|---|---|---|---|---|---|

| 0.5 bar | 1 bar | 2 bar | 3 bar | 4 bar | 5 bar | 6 bar | |

| kW | kW | kW | kW | kW | kW | kW | |

| IN THE 33-101 | 34 | 45 | 61 | 73 | 83 | 93 | 101 |

| IN THE 67-202 | 67 | 81 | 122 | 145 | 166 | 186 | 202 |

| IN THE 101-303 | 101 | 134 | 183 | 218 | 249 | 279 | 303 |

| IN THE 135-404 | 135 | 179 | 245 | 291 | 331 | 372 | 405 |

| IN THE 168-506 | 169 | 224 | 306 | 363 | 414 | 465 | 506 |

| IN THE 202-607 | 202 | 269 | 367 | 436 | 497 | 558 | 607 |

| IN THE 270-810 | 270 | 358 | 488 | 581 | 663 | 744 | 809 |

| IN THE 337-1011 | 337 | 448 | 612 | 727 | 828 | 930 | 1.012 |

| IN THE 421-1264 | 422 | 560 | 765 | 908 | 1.036 | 1.163 | 1.264 |

| IN THE 505-1517 | 506 | 672 | 917 | 1.090 | 1.243 | 1.395 | 1.517 |

| IN THE 590-1770 | 590 | 783 | 1.070 | 1.272 | 1.450 | 1.628 | 1.770 |

| IN THE 674-2023 | 674 | 895 | 1.223 | 1.453 | 1.657 | 1.860 | 2.023 |

| IN THE 843-2530 | 843 | 1.119 | 1.529 | 1.817 | 2.071 | 2.326 | 2.529 |

| IN THE 1011-3035 | 1.012 | 1.343 | 1.835 | 2.180 | 2.485 | 2.791 | 3.035 |

| IN THE 1180-3540 | 1.180 | 1.567 | 2.141 | 2.544 | 2.900 | 3.256 | 3.541 |

| IN THE 1348-4046 | 1.349 | 1.791 | 2.447 | 2.907 | 3.314 | 3.721 | 4.047 |

| IN THE 1517-4552 | 1.517 | 2.014 | 2.752 | 3.270 | 3.728 | 4.186 | 4.552 |

| IN THE 1686-5058 | 1.686 | 2.238 | 3.058 | 3.634 | 4.142 | 4.651 | 5.058 |

| IN THE 2023-6070 | 2.023 | 2.686 | 3.670 | 4.360 | 4.971 | 5.581 | 6.070 |

| IN THE 2360-7081 | 2.360 | 3.134 | 4.281 | 5.087 | 5.799 | 6.512 | 7.081 |

| IN THE 2697-8093 | 2.698 | 3.581 | 4.893 | 5.814 | 6.628 | 7.442 | 8.093 |

Make the Right Choice in Shell & Tube Heat Exchanger Selection!

When selecting a shell & tube heat exchanger, you can use two different tables to determine the most suitable model for your system. The first table provides information on hot water production capacities based on steam capacity, while the second table indicates how much heat transfer (kW) can be achieved at different pressure levels.

By using these two tables, you can:

✅ Determine the appropriate pressure range for product selection.

✅ Find the most efficient heat exchanger based on your heat demand and operating conditions.

✅ Select the correct article number from the connection size tables to place an accurate order.

📌 Article numbers ensure accurate ordering after the selection process by reflecting the operating pressure, heat transfer capacity, and connection sizes.

Instead of selecting from the tables, you can also share your requirements by filling out the inquiry form. Our expert team will identify the most suitable shell & tube heat exchanger for your process and provide the most efficient solution.

📩 Fill out the form now, and let us select the best heat exchanger for you! 🚀

Inquiry FormCapacity and Connection Size Table for 0.5 BAR Steam Pressure

| Model | Ürün Kodu | L Toplam Boy | H Toplam Yükseklik | D Ø Çap | d1 Buhar Giriş | d2 Kondens Çıkış | d3 Su Girişi | d4 Su Çıkışı | d5 Boşaltma |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | DN | DN | DN | DN | DN | ||

| IN THE 33-101 | 0.5Pr1W7090S1250 | 1950 | 1310 | 160 | 32 | 20 | 25 | 25 | 20 |

| IN THE 67-202 | 0.5Pr2W7090S1500 | 2200 | 1350 | 200 | 40 | 20 | 32 | 32 | 20 |

| IN THE 101-303 | 0.5Pr3W7090S1500 | 2200 | 1400 | 250 | 50 | 20 | 40 | 40 | 20 |

| IN THE 135-404 | 0.5Pr4W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 50 | 50 | 20 |

| IN THE 168-506 | 0.5Pr5W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 50 | 50 | 20 |

| IN THE 202-607 | 0.5Pr6W7090S1500 | 2200 | 1450 | 300 | 80 | 20 | 65 | 65 | 20 |

| IN THE 270-810 | 0.5Pr8W7090S1500 | 2200 | 1550 | 400 | 100 | 20 | 65 | 65 | 20 |

| IN THE 337-1011 | 0.5Pr10W7090S2000 | 2700 | 1550 | 400 | 100 | 20 | 80 | 80 | 20 |

| IN THE 421-1264 | 0.5Pr12.5W7090S2000 | 2700 | 1650 | 500 | 100 | 25 | 80 | 80 | 20 |

| IN THE 505-1517 | 0.5Pr15W7090S2000 | 2700 | 1650 | 500 | 125 | 25 | 100 | 100 | 20 |

| IN THE 590-1770 | 0.5Pr17.5W7090S2000 | 2700 | 1650 | 500 | 125 | 25 | 100 | 100 | 20 |

| IN THE 674-2023 | 0.5Pr20W7090S2000 | 2700 | 1650 | 500 | 150 | 32 | 100 | 100 | 20 |

| IN THE 843-2530 | 0.5Pr25W7090S2000 | 2700 | 1750 | 600 | 150 | 32 | 125 | 125 | 20 |

| IN THE 1011-3035 | 0.5Pr30W7090S2000 | 2700 | 1750 | 600 | 150 | 32 | 125 | 125 | 20 |

| IN THE 1180-3540 | 0.5Pr35W7090S3000 | 3700 | 1750 | 600 | 200 | 40 | 150 | 150 | 20 |

| IN THE 1348-4046 | 0.5Pr40W7090S3000 | 3700 | 1750 | 600 | 200 | 40 | 150 | 150 | 20 |

| IN THE 1517-4552 | 0.5Pr45W7090S3000 | 3700 | 1750 | 600 | 200 | 50 | 150 | 150 | 20 |

| IN THE 1686-5058 | 0.5Pr50W7090S3000 | 3700 | 1850 | 700 | 200 | 50 | 200 | 200 | 20 |

| IN THE 2023-6070 | 0.5Pr60W7090S3000 | 3700 | 1850 | 700 | 250 | 50 | 200 | 200 | 20 |

| IN THE 2360-7081 | 0.5Pr70W7090S3000 | 3700 | 1950 | 800 | 250 | 65 | 200 | 200 | 20 |

| IN THE 2697-8093 | 0.5Pr80W7090S3000 | 3700 | 1950 | 800 | 250 | 65 | 200 | 200 | 20 |

Capacity and Connection Size Table for 1 BAR Steam Pressure

| Model | Ürün Kodu | L Toplam Boy | H Toplam Yükseklik | D Ø Çap | d1 Buhar Giriş | d2 Kondens Çıkış | d3 Su Girişi | d4 Su Çıkışı | d5 Boşaltma |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | DN | DN | DN | DN | DN | ||

| IN THE 33-101 | 1Pr1W7090S1250 | 1950 | 1310 | 160 | 32 | 20 | 32 | 32 | 20 |

| IN THE 67-202 | 1Pr2W7090S1500 | 2200 | 1350 | 200 | 50 | 20 | 40 | 40 | 20 |

| IN THE 101-303 | 1Pr3W7090S1500 | 2200 | 1400 | 250 | 50 | 20 | 50 | 50 | 20 |

| IN THE 135-404 | 1Pr4W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 50 | 50 | 20 |

| IN THE 168-506 | 1Pr5W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 65 | 65 | 20 |

| IN THE 202-607 | 1Pr6W7090S1500 | 2200 | 1450 | 300 | 80 | 20 | 65 | 65 | 20 |

| IN THE 270-810 | 1Pr8W7090S1500 | 2200 | 1550 | 400 | 80 | 20 | 80 | 80 | 20 |

| IN THE 337-1011 | 1Pr10W7090S2000 | 2700 | 1550 | 400 | 100 | 25 | 80 | 80 | 20 |

| IN THE 421-1264 | 1Pr12.5W7090S2000 | 2700 | 1650 | 500 | 100 | 25 | 100 | 100 | 20 |

| IN THE 505-1517 | 1Pr15W7090S2000 | 2700 | 1650 | 500 | 125 | 32 | 100 | 100 | 20 |

| IN THE 590-1770 | 1Pr17.5W7090S2000 | 2700 | 1650 | 500 | 125 | 32 | 125 | 125 | 20 |

| IN THE 674-2023 | 1Pr20W7090S2000 | 2700 | 1650 | 500 | 150 | 32 | 125 | 125 | 20 |

| IN THE 843-2530 | 1Pr25W7090S2000 | 2700 | 1750 | 600 | 150 | 40 | 125 | 125 | 20 |

| IN THE 1011-3035 | 1Pr30W7090S2000 | 2700 | 1750 | 600 | 150 | 40 | 150 | 150 | 20 |

| IN THE 1180-3540 | 1Pr35W7090S3000 | 3700 | 1750 | 600 | 200 | 50 | 150 | 150 | 20 |

| IN THE 1348-4046 | 1Pr40W7090S3000 | 3700 | 1750 | 600 | 200 | 50 | 150 | 150 | 20 |

| IN THE 1517-4552 | 1Pr45W7090S3000 | 3700 | 1750 | 600 | 200 | 50 | 200 | 200 | 20 |

| IN THE 1686-5058 | 1Pr50W7090S3000 | 3700 | 1850 | 700 | 200 | 50 | 200 | 200 | 20 |

| IN THE 2023-6070 | 1Pr60W7090S3000 | 3700 | 1850 | 700 | 250 | 65 | 200 | 200 | 20 |

| IN THE 2360-7081 | 1Pr70W7090S3000 | 3700 | 1950 | 800 | 250 | 65 | 250 | 250 | 20 |

| IN THE 2697-8093 | 1Pr80W7090S3000 | 3700 | 1950 | 800 | 300 | 65 | 250 | 250 | 20 |

Capacity and Connection Size Table for 2 BAR Steam Pressure

| Model | Ürün Kodu | L Toplam Boy | H Toplam Yükseklik | D Ø Çap | d1 Buhar Giriş | d2 Kondens Çıkış | d3 Su Girişi | d4 Su Çıkışı | d5 Boşaltma |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | DN | DN | DN | DN | DN | ||

| IN THE 33-101 | 1Pr1W7090S1250 | 1950 | 1310 | 160 | 32 | 20 | 32 | 32 | 20 |

| IN THE 67-202 | 1Pr2W7090S1500 | 2200 | 1350 | 200 | 50 | 20 | 40 | 40 | 20 |

| IN THE 101-303 | 1Pr3W7090S1500 | 2200 | 1400 | 250 | 50 | 20 | 50 | 50 | 20 |

| IN THE 135-404 | 1Pr4W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 50 | 50 | 20 |

| IN THE 168-506 | 1Pr5W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 65 | 65 | 20 |

| IN THE 202-607 | 1Pr6W7090S1500 | 2200 | 1450 | 300 | 80 | 20 | 65 | 65 | 20 |

| IN THE 270-810 | 1Pr8W7090S1500 | 2200 | 1550 | 400 | 80 | 20 | 80 | 80 | 20 |

| IN THE 337-1011 | 1Pr10W7090S2000 | 2700 | 1550 | 400 | 100 | 25 | 80 | 80 | 20 |

| IN THE 421-1264 | 1Pr12.5W7090S2000 | 2700 | 1650 | 500 | 100 | 25 | 100 | 100 | 20 |

| IN THE 505-1517 | 1Pr15W7090S2000 | 2700 | 1650 | 500 | 125 | 32 | 100 | 100 | 20 |

| IN THE 590-1770 | 1Pr17.5W7090S2000 | 2700 | 1650 | 500 | 125 | 32 | 125 | 125 | 20 |

| IN THE 674-2023 | 1Pr20W7090S2000 | 2700 | 1650 | 500 | 150 | 32 | 125 | 125 | 20 |

| IN THE 843-2530 | 1Pr25W7090S2000 | 2700 | 1750 | 600 | 150 | 40 | 125 | 125 | 20 |

| IN THE 1011-3035 | 1Pr30W7090S2000 | 2700 | 1750 | 600 | 150 | 40 | 150 | 150 | 20 |

| IN THE 1180-3540 | 1Pr35W7090S3000 | 3700 | 1750 | 600 | 200 | 50 | 150 | 150 | 20 |

| IN THE 1348-4046 | 1Pr40W7090S3000 | 3700 | 1750 | 600 | 200 | 50 | 150 | 150 | 20 |

| IN THE 1517-4552 | 1Pr45W7090S3000 | 3700 | 1750 | 600 | 200 | 50 | 200 | 200 | 20 |

| IN THE 1686-5058 | 1Pr50W7090S3000 | 3700 | 1850 | 700 | 200 | 50 | 200 | 200 | 20 |

| IN THE 2023-6070 | 1Pr60W7090S3000 | 3700 | 1850 | 700 | 250 | 65 | 200 | 200 | 20 |

| IN THE 2360-7081 | 1Pr70W7090S3000 | 3700 | 1950 | 800 | 250 | 65 | 250 | 250 | 20 |

| IN THE 2697-8093 | 1Pr80W7090S3000 | 3700 | 1950 | 800 | 300 | 65 | 250 | 250 | 20 |

Capacity and Connection Size Table for 3 BAR Steam Pressure

| Model | Ürün Kodu | L Toplam Boy | H Toplam Yükseklik | D Ø Çap | d1 Buhar Giriş | d2 Kondens Çıkış | d3 Su Girişi | d4 Su Çıkışı | d5 Boşaltma |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | DN | DN | DN | DN | DN | ||

| IN THE 33-101 | 3Pr1W7090S1250 | 1950 | 1310 | 160 | 32 | 20 | 40 | 40 | 20 |

| IN THE 67-202 | 3Pr2W7090S1500 | 2200 | 1350 | 200 | 40 | 20 | 50 | 50 | 20 |

| IN THE 101-303 | .3Pr3W7090S1500 | 2200 | 1400 | 250 | 50 | 20 | 65 | 65 | 20 |

| IN THE 135-404 | 3Pr4W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 65 | 65 | 20 |

| IN THE 168-506 | 3Pr5W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 80 | 80 | 20 |

| IN THE 202-607 | 3Pr6W7090S1500 | 2200 | 1450 | 300 | 80 | 20 | 80 | 80 | 20 |

| IN THE 270-810 | 3Pr8W7090S1500 | 2200 | 1550 | 400 | 80 | 25 | 100 | 100 | 20 |

| IN THE 337-1011 | 3Pr10W7090S2000 | 2700 | 1550 | 400 | 100 | 32 | 100 | 100 | 20 |

| IN THE 421-1264 | 3Pr12.5W7090S2000 | 2700 | 1650 | 500 | 100 | 32 | 125 | 125 | 20 |

| IN THE 505-1517 | 3Pr15W7090S2000 | 2700 | 1650 | 500 | 125 | 40 | 125 | 125 | 20 |

| IN THE 590-1770 | 3Pr17.5W7090S2000 | 2700 | 1650 | 500 | 125 | 40 | 150 | 150 | 20 |

| IN THE 674-2023 | 3Pr20W7090S2000 | 2700 | 1650 | 500 | 125 | 40 | 150 | 150 | 20 |

| IN THE 843-2530 | 3Pr25W7090S2000 | 2700 | 1750 | 600 | 150 | 50 | 150 | 150 | 20 |

| IN THE 1011-3035 | 3Pr30W7090S2000 | 2700 | 1750 | 600 | 150 | 50 | 200 | 200 | 20 |

| IN THE 1180-3540 | 3Pr35W7090S3000 | 3700 | 1750 | 600 | 200 | 50 | 200 | 200 | 20 |

| IN THE 1348-4046 | 3Pr40W7090S3000 | 3700 | 1750 | 600 | 200 | 65 | 200 | 200 | 20 |

| IN THE 1517-4552 | 3Pr45W7090S3000 | 3700 | 1750 | 600 | 200 | 65 | 250 | 250 | 20 |

| IN THE 1686-5058 | 3Pr50W7090S3000 | 3700 | 1850 | 700 | 200 | 65 | 250 | 250 | 20 |

| IN THE 2023-6070 | 3Pr60W7090S3000 | 3700 | 1850 | 700 | 250 | 80 | 250 | 250 | 20 |

| IN THE 2360-7081 | 3Pr70W7090S3000 | 3700 | 1950 | 800 | 250 | 80 | 300 | 300 | 20 |

| IN THE 2697-8093 | 3Pr80W7090S3000 | 3700 | 1950 | 800 | 250 | 80 | 300 | 300 | 20 |

Capacity and Connection Size Table for 4 BAR Steam Pressure

| Model | Ürün Kodu | L Toplam Boy | H Toplam Yükseklik | D Ø Çap | d1 Buhar Giriş | d2 Kondens Çıkış | d3 Su Girişi | d4 Su Çıkışı | d5 Boşaltma |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | DN | DN | DN | DN | DN | ||

| IN THE 33-101 | 4Pr1W7090S1250 | 1950 | 1310 | 160 | 32 | 20 | 40 | 40 | 20 |

| IN THE 67-202 | 4Pr2W7090S1500 | 2200 | 1350 | 200 | 40 | 20 | 50 | 50 | 20 |

| IN THE 101-303 | 4Pr3W7090S1500 | 2200 | 1400 | 250 | 50 | 20 | 65 | 65 | 20 |

| IN THE 135-404 | 4Pr4W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 80 | 80 | 20 |

| IN THE 168-506 | 4Pr5W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 80 | 80 | 20 |

| IN THE 202-607 | 4Pr6W7090S1500 | 2200 | 1450 | 300 | 65 | 25 | 100 | 100 | 20 |

| IN THE 270-810 | 4Pr8W7090S1500 | 2200 | 1550 | 400 | 80 | 25 | 100 | 100 | 20 |

| IN THE 337-1011 | 4Pr10W7090S2000 | 2700 | 1550 | 400 | 100 | 32 | 125 | 125 | 20 |

| IN THE 421-1264 | 4Pr12.5W7090S2000 | 2700 | 1650 | 500 | 100 | 32 | 125 | 125 | 20 |

| IN THE 505-1517 | 4Pr15W7090S2000 | 2700 | 1650 | 500 | 100 | 40 | 150 | 150 | 20 |

| IN THE 590-1770 | 4Pr17.5W7090S2000 | 2700 | 1650 | 500 | 125 | 40 | 150 | 150 | 20 |

| IN THE 674-2023 | 4Pr20W7090S2000 | 2700 | 1650 | 500 | 125 | 40 | 150 | 150 | 20 |

| IN THE 843-2530 | 4Pr25W7090S2000 | 2700 | 1750 | 600 | 150 | 50 | 200 | 200 | 20 |

| IN THE 1011-3035 | 4Pr30W7090S2000 | 2700 | 1750 | 600 | 150 | 65 | 200 | 200 | 20 |

| IN THE 1180-3540 | 4Pr35W7090S3000 | 3700 | 1750 | 600 | 200 | 65 | 200 | 200 | 20 |

| IN THE 1348-4046 | 4Pr40W7090S3000 | 3700 | 1750 | 600 | 200 | 65 | 250 | 250 | 20 |

| IN THE 1517-4552 | 4Pr45W7090S3000 | 3700 | 1750 | 600 | 200 | 65 | 250 | 250 | 20 |

| IN THE 1686-5058 | 4Pr50W7090S3000 | 3700 | 1850 | 700 | 200 | 80 | 250 | 250 | 20 |

| IN THE 2023-6070 | 4Pr60W7090S3000 | 3700 | 1850 | 700 | 250 | 80 | 300 | 300 | 20 |

| IN THE 2360-7081 | 4Pr70W7090S3000 | 3700 | 1950 | 800 | 250 | 80 | 300 | 300 | 20 |

| IN THE 2697-8093 | 4Pr80W7090S3000 | 3700 | 1950 | 800 | 250 | 100 | 300 | 300 | 20 |

Capacity and Connection Size Table for 5 BAR Steam Pressure

| Model | Ürün Kodu | L Toplam Boy | H Toplam Yükseklik | D Ø Çap | d1 Buhar Giriş | d2 Kondens Çıkış | d3 Su Girişi | d4 Su Çıkışı | d5 Boşaltma |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | DN | DN | DN | DN | DN | ||

| IN THE 33-101 | 5Pr1W7090S1250 | 1950 | 1310 | 160 | 32 | 20 | 40 | 40 | 20 |

| IN THE 67-202 | 5Pr2W7090S1500 | 2200 | 1350 | 200 | 40 | 20 | 50 | 50 | 20 |

| IN THE 101-303 | 5Pr3W7090S1500 | 2200 | 1400 | 250 | 50 | 20 | 65 | 65 | 20 |

| IN THE 135-404 | 5Pr4W7090S1500 | 2200 | 1450 | 300 | 50 | 20 | 80 | 80 | 20 |

| IN THE 168-506 | 5Pr5W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 80 | 80 | 20 |

| IN THE 202-607 | 5Pr6W7090S1500 | 2200 | 1450 | 300 | 65 | 25 | 100 | 100 | 20 |

| IN THE 270-810 | .5Pr8W7090S1500 | 2200 | 1550 | 400 | 80 | 32 | 100 | 100 | 20 |

| IN THE 337-1011 | 5Pr10W7090S2000 | 2700 | 1550 | 400 | 80 | 32 | 125 | 125 | 20 |

| IN THE 421-1264 | 5Pr12.5W7090S2000 | 2700 | 1650 | 500 | 100 | 40 | 125 | 125 | 20 |

| IN THE 505-1517 | 5Pr15W7090S2000 | 2700 | 1650 | 500 | 100 | 40 | 125 | 125 | 20 |

| IN THE 590-1770 | 5Pr17.5W7090S2000 | 2700 | 1650 | 500 | 125 | 50 | 150 | 150 | 20 |

| IN THE 674-2023 | 5Pr20W7090S2000 | 2700 | 1650 | 500 | 125 | 50 | 150 | 150 | 20 |

| IN THE 843-2530 | 5Pr25W7090S2000 | 2700 | 1750 | 600 | 150 | 50 | 200 | 200 | 20 |

| IN THE 1011-3035 | 5Pr30W7090S2000 | 2700 | 1750 | 600 | 150 | 65 | 200 | 200 | 20 |

| IN THE 1180-3540 | 5Pr35W7090S3000 | 3700 | 1750 | 600 | 150 | 65 | 200 | 200 | 20 |

| IN THE 1348-4046 | 5Pr40W7090S3000 | 3700 | 1750 | 600 | 200 | 65 | 250 | 250 | 20 |

| IN THE 1517-4552 | 5Pr45W7090S3000 | 3700 | 1750 | 600 | 200 | 80 | 250 | 250 | 20 |

| IN THE 1686-5058 | 5Pr50W7090S3000 | 3700 | 1850 | 700 | 200 | 80 | 250 | 250 | 20 |

| IN THE 2023-6070 | 5Pr60W7090S3000 | 3700 | 1850 | 700 | 200 | 80 | 250 | 250 | 20 |

| IN THE 2360-7081 | 5Pr70W7090S3000 | 3700 | 1950 | 800 | 250 | 100 | 300 | 300 | 20 |

| IN THE 2697-8093 | 5Pr80W7090S3000 | 3700 | 1950 | 800 | 250 | 100 | 350 | 350 | 20 |

Capacity and Connection Size Table for 6 BAR Steam Pressure

| Model | Ürün Kodu | L Toplam Boy | H Toplam Yükseklik | D Ø Çap | d1 Buhar Giriş | d2 Kondens Çıkış | d3 Su Girişi | d4 Su Çıkışı | d5 Boşaltma |

|---|---|---|---|---|---|---|---|---|---|

| mm | mm | mm | DN | DN | DN | DN | DN | ||

| IN THE 33-101 | 6Pr1W7090S1250 | 1950 | 1310 | 160 | 25 | 20 | 40 | 40 | 20 |

| IN THE 67-202 | 6Pr2W7090S1500 | 2200 | 1350 | 200 | 32 | 20 | 50 | 50 | 20 |

| IN THE 101-303 | 6Pr3W7090S1500 | 2200 | 1400 | 250 | 50 | 20 | 65 | 65 | 20 |

| IN THE 135-404 | 6Pr4W7090S1500 | 2200 | 1450 | 300 | 50 | 20 | 80 | 80 | 20 |

| IN THE 168-506 | 6Pr5W7090S1500 | 2200 | 1450 | 300 | 65 | 20 | 80 | 80 | 20 |

| IN THE 202-607 | 6Pr6W7090S1500 | 2200 | 1450 | 300 | 65 | 25 | 100 | 100 | 20 |

| IN THE 270-810 | 6Pr8W7090S1500 | 2200 | 1550 | 400 | 80 | 32 | 100 | 100 | 20 |

| IN THE 337-1011 | 6Pr10W7090S2000 | 2700 | 1550 | 400 | 80 | 32 | 125 | 125 | 20 |

| IN THE 421-1264 | 6Pr12.5W7090S2000 | 2700 | 1650 | 500 | 100 | 40 | 125 | 125 | 20 |

| IN THE 505-1517 | 6Pr15W7090S2000 | 2700 | 1650 | 500 | 100 | 40 | 150 | 150 | 20 |

| IN THE 590-1770 | 6Pr17.5W7090S2000 | 2700 | 1650 | 500 | 100 | 50 | 150 | 150 | 20 |

| IN THE 674-2023 | 6Pr20W7090S2000 | 2700 | 1650 | 500 | 125 | 50 | 150 | 150 | 20 |

| IN THE 843-2530 | 6Pr25W7090S2000 | 2700 | 1750 | 600 | 125 | 50 | 200 | 200 | 20 |

| IN THE 1011-3035 | 6Pr30W7090S2000 | 2700 | 1750 | 600 | 150 | 65 | 200 | 200 | 20 |

| IN THE 1180-3540 | 6Pr35W7090S3000 | 3700 | 1750 | 600 | 150 | 65 | 250 | 250 | 20 |

| IN THE 1348-4046 | 6Pr40W7090S3000 | 3700 | 1750 | 600 | 150 | 65 | 250 | 250 | 20 |

| IN THE 1517-4552 | 6Pr45W7090S3000 | 3700 | 1750 | 600 | 200 | 80 | 250 | 250 | 20 |

| IN THE 1686-5058 | 6Pr50W7090S3000 | 3700 | 1850 | 700 | 200 | 80 | 250 | 250 | 20 |

| IN THE 2023-6070 | 6Pr60W7090S3000 | 3700 | 1850 | 700 | 200 | 80 | 300 | 300 | 20 |

| IN THE 2360-7081 | 6Pr70W7090S3000 | 3700 | 1950 | 800 | 200 | 100 | 300 | 300 | 20 |

| IN THE 2697-8093 | 6Pr80W7090S3000 | 3700 | 1950 | 800 | 250 | 100 | 300 | 300 | 20 |

Shell & Tube Heat Exchanger Applications – Industry-Specific Solutions

Use of Shell & Tube Heat Exchangers in Industrial Facilities

🏭 Food Industry:Shell & tube heat exchangers ensure precise temperature control in food production processes such as pasteurization, sterilization, and fruit juice production.

👕 Textile Industry:Industrial shell & tube heat exchangers are used in dyeing, drying, and pressing processes, integrating seamlessly with hot water and steam systems

🛢️ Chemical & Petrochemical Industry: In chemical processes, shell & tube heat exchangers provide efficient solutions for solvent evaporation, reactor temperature control, and various petrochemical applications.

📄 Pulp & Paper Industry: In paper production, shell & tube heat exchangers enhance heat transfer efficiency in pulp preparation and paper drying processes.

Shell & Tube Heat Exchangers in Commercial and Residential Applications

🏨 Hotels & Resorts: Shell & tube heat exchangers provide efficient hot water solutions for room heating, pool water heating, and SPA systems in hotels and resorts.

🏥 Hospitals: Used in sterilization systems, shell & tube heat exchangers support operating room hygiene and meet centralized hot water demands.

🏢 Shopping Malls & Large Buildings:

In central heating systems, shell & tube heat exchangers ensure high efficiency in hot water distribution.

🏫 Schools & Universities: In dormitories, cafeterias, and laboratories, shell & tube heat exchangers contribute to energy savings by integrating with hot water and central heating systems.

Shell & Tube Heat Exchangers in Heating & District Heating Systems

🏠 Central Heating Systems: In residential projects, shell & tube heat exchangers can be integrated into central hot water and heating systems

🌍 District Heating: Used in cities, industrial facilities, and large campuses, shell & tube heat exchangers provide large-scale heating solutions.

Use of Shell & Tube Heat Exchangers in Agriculture & Livestock

🌿 Greenhouses: Shell & tube heat exchangers provide stable and efficient heat transfer for root heating and maintaining optimal indoor temperatures in greenhouse farming.

🐄 Livestock Farming:

In livestock facilities, shell & tube heat exchangers meet the hot water demands of barns, poultry houses, and hatcheries, ensuring a healthy environment for animal growth. For feedlots, these heat exchanger solutions offer fuel savings and lower operating costs in water heating systems.

Русский

Русский Türkçe

Türkçe