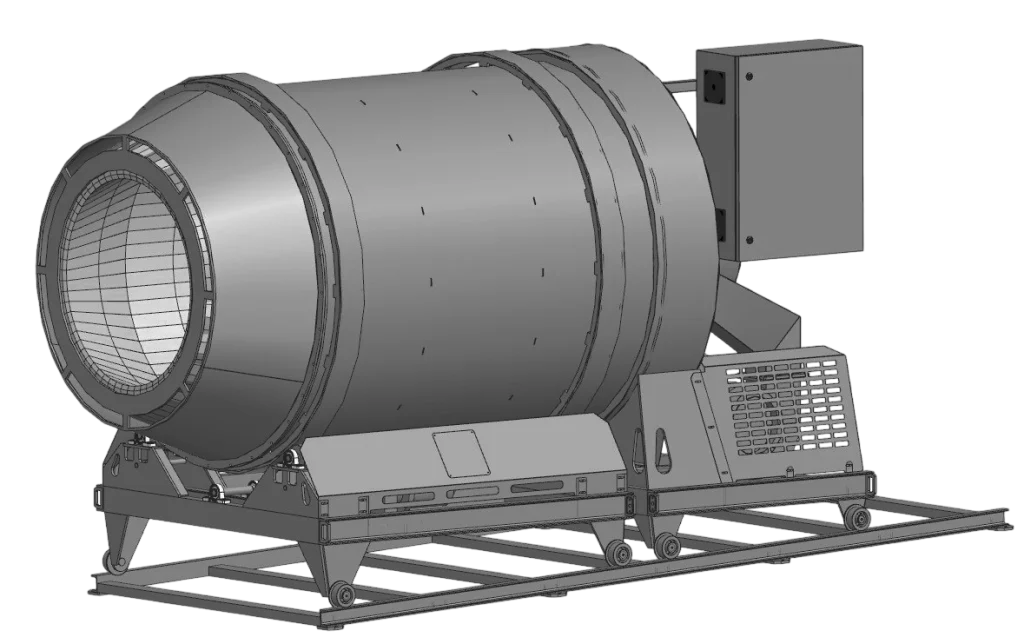

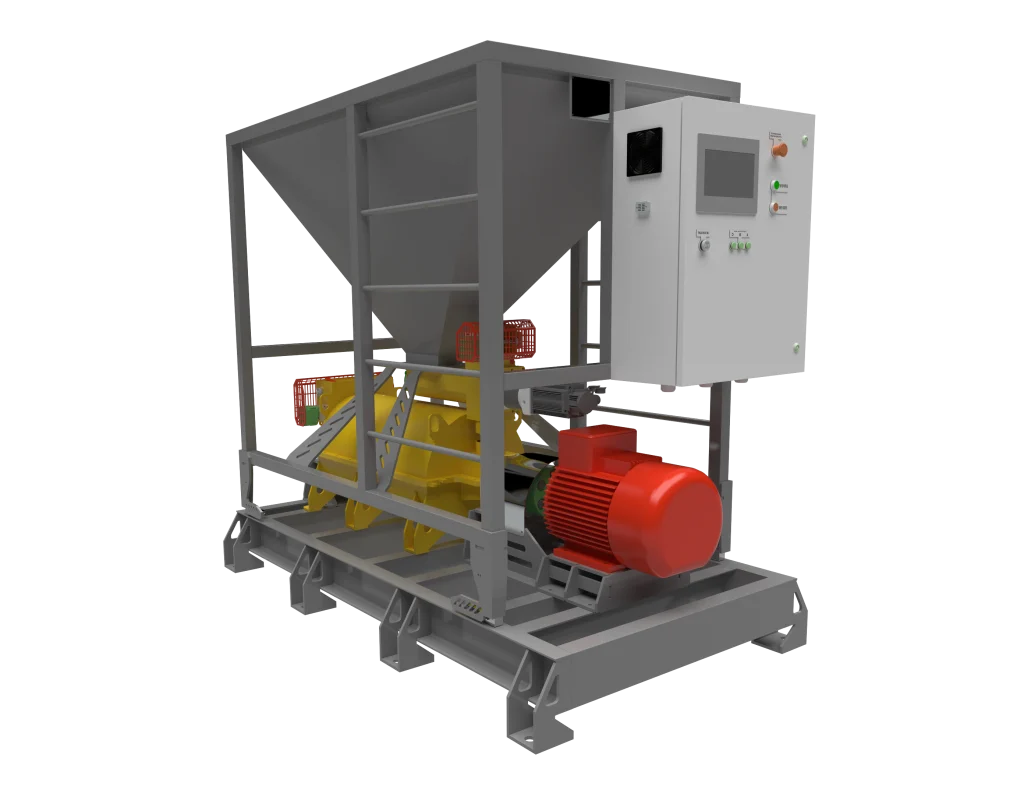

Pulverized Coal Burner System

High-Efficiency, Environmentally Friendly, and Economical Industrial Burner System

The Pulverized Coal Burner System works on the principle of gasifying pulverized coal in the combustion chamber, providing high-efficiency and environmentally friendly heating solutions for industrial applications. This system ensures energy savings in industrial facilities and achieves optimal efficiency in coal combustion processes with its powerful and reliable performance.

Capacity Range

🔹 INCBR1000 Model: 300 kW – 1300 kW

🔹 INCBR3000 Model: 950 kW – 4000 kW

Fuel Types: Coal and pelletized biomass (compatible with various types of coal and biomass with different calorific values)

Control System: The combustion process and system performance can be remotely monitored and controlled with a PLC-based automation system.

⭐ Customized production can be made with different capacities and design options for special orders or project requirements.

Each Product Is Subjected to a Combustion Test Prior to Shipment

Before Each Shipment, the Devices Are Subjected to a Final Combustion Test as Part of Quality Control. This test is performed to verify the device’s performance, combustion efficiency, and safety systems. During the combustion test, the burner’s ignition, fuel supply, air-fuel ratio control, ignition system stability, temperature sensor accuracy, and flue gas emissions are monitored. Additionally, the temperature distribution and pressure values in the combustion chamber are analyzed to assess the device’s suitability for operation under field conditions. The aim of this test is to ensure the safety and operational efficiency of the device.

Coal Burner Technical Specifications

| Model | IN CBR 1000 | IN CBR 3000 |

|---|---|---|

| Fuel Type | Coal, Sunflower Husk Pellets, and Other Similar Solid Fuels | |

| Combustion Capacity | 10 – 200 kg/h | 150 – 600 kg/h |

| Fuel Feed Bunker Volume | 0,4 m³ | 0,8 m³ |

| Fuel Size | 3 mm – 20 mm | |

| Fuel Feeding System | Proportional | |

| Supply Voltage | Three-phase 380 V ±5%, 50 Hz (ground connection is required) | |

| Electrical Power Consumption (At Full Load) | 6,5 kW | 17 kW |

| Automatic Fuel Weight Measurement | 0 – 350 kg | 0-650 kg |

| (Level control function available to provide stop/start signal for automatic filling of the feed bunker) | ||

| Control Interface | Control via Touchscreen HMI connected to PLC | |

| Combustion Air Flow Control System | Proportional | |

| Temperature Measurement Points | Bearings on Shafts, Servo Motor, Main Shaft Motor, Panel Internal and External Temperature | |

| Equipment Weight | 450 kg | 1100 kg |

Recommended Coal Parameters

| Parameter | Value Range |

|---|---|

| Lower Heating Value (LHV) | 5200 – 6500 kcal/kg |

| Ash Content | %5 – %12 |

| Moisture Content | %8 – %15 |

| Volatile Matter | %18 and above |

| Carbon Content | %50 – %75 |

| Sulfur Content | %0.5 – %1.5 |

| Combustion Temperature | 800°C – 1200°C |

| Granule Size | 3 mm – 20 mm |

| Reactivity Rate | %90 – %95 |

Application Areas of Insuz CBR Model Coal Burner

Industrial Facilities

Food Industry: In food production facilities, coal burners are used as a heat source for steam and hot water production. The consistent heat required for pasteurization, sterilization, and cleaning lines is efficiently provided by solid fuel systems.

Textile Industry: In textile dyeing and drying lines, coal burner boiler systems provide stable heat generation at a constant temperature, ensuring stability in production processes. Coal-fired systems are preferred for reducing energy costs.

Asphalt Plants: In asphalt production, coal burner systems are an ideal energy source for heating and drying aggregates. They offer low operating costs and high thermal capacity.

Lime Kiln Plants: The stable and high temperatures required in lime kilns are achieved with coal burners. Stable combustion and temperature control during the calcination process improve process quality.

Large Commercial and Residential Applications

Hotels and Resorts: Coal burners used in solid fuel boiler systems provide hot water production in large-scale facilities such as hotels and resorts. They ensure a continuous supply of hot water 24/7 via a central system.

Hospitals: Coal-fired central boiler systems can be preferred to meet the continuous hygienic hot water demand. Redundant system designs support uninterrupted service delivery.

Shopping Malls and Large Buildings: In buildings like shopping malls and office towers, coal burners integrated into HVAC systems meet the central heating and hot water needs.

Schools and Universities: The hot water demand for showers, cafeterias, and laboratories in educational institutions can be met with high-capacity coal burner boiler systems. Their long lifespan and durability reduce maintenance requirements.

Heating Systems and District Heating

Central Heating Systems: Coal burner boiler systems provide central heating solutions for apartment buildings and residential projects. Due to low fuel costs, they are preferred in large-scale housing projects.

District Heating: In city heating projects, large-capacity coal boiler systems used by municipalities and cooperatives work in integration with central burner systems. This ensures sustainable heating across wide areas.

Agriculture and Greenhouse Applications

Greenhouses: Coal burner hot water systems are used for soil and air heating in greenhouses. These systems, which support plant growth through climate control, make agricultural production more cost-effective due to low fuel costs.

Livestock Farming: Coal burner boiler systems used for heating barns, poultry houses, and hatcheries provide ideal temperature conditions for animal health and productivity. These systems also support hygienic hot water supply in agricultural operations.

Русский

Русский Türkçe

Türkçe