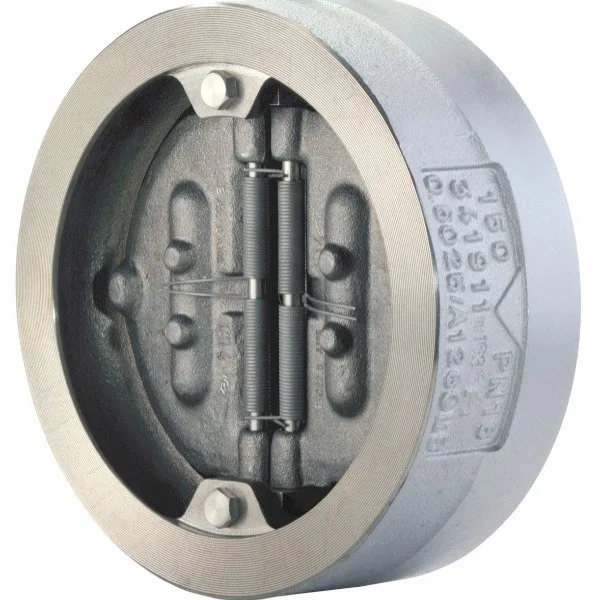

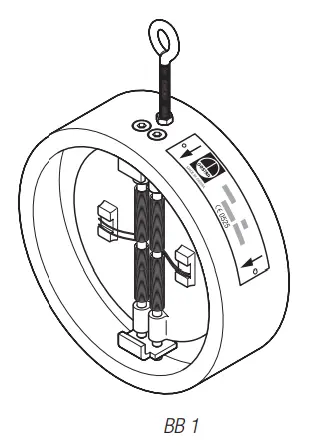

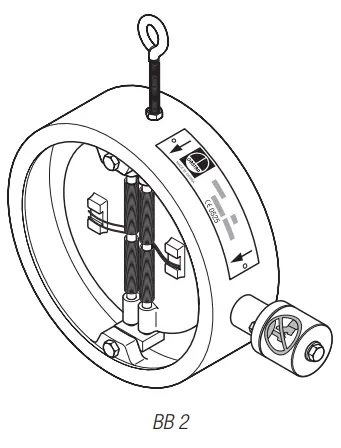

GESTRA BB 1 – BB 2 Series Swing Check Valves

GESTRA BB 1 – BB 2 Series Swing Check Valves

Type: Dual-Plate Wafer-Type Swing Check Valves

Size Range: DN 50 – DN 1200 (2″ – 48″)

Pressure Ratings: PN 6 / 10 / 16 / 25 / 40 | ASME Class 125 / 150 / 300

Mounting: Between flanges (wafer-type)

Flow Media: Liquids, gases, steam

🔧 Description

The GESTRA BB 1 and BB 2 Series Swing Check Valves are wafer-type dual-plate non-return valves engineered to prevent backflow in industrial pipelines. Featuring a center-guided twin-disc swing design, these valves offer low pressure loss, high reliability, and long-term performance even in demanding systems.

Their compact and lightweight construction makes them ideal for space-restricted installations. The valve body is centered between flanges and allows installation in horizontal or vertical flow (upward direction only for vertical). The dual-disc configuration ensures quick closure and reduced water hammer risk.

GESTRA BB 1 and BB 2 series are built in accordance with DIN EN 558-1, Series 16 (face-to-face length), and are available in both DIN and ASME flange standards.

🌍 Typical Applications

Industrial steam and condensate systems

Hot and chilled water networks

Chemical and petrochemical pipelines

HVAC and building services systems

Process engineering plants

Pump discharge lines

Utility and district heating systems

Compressed air and inert gas applications

💡 Key Benefits

✅ Dual-plate swing design minimizes water hammer and ensures fast shut-off

🔩 Wafer-type body enables compact installation between standard flanges

🔄 Horizontal and vertical mounting (upward flow) supported

💧 Very low pressure loss due to optimized disc geometry

🧱 Rugged construction for extended service life and operational safety

🌐 Available for DIN and ASME flanges, making it suitable for global installations

🔒 Tight sealing and reliable non-return function for steam, liquid, and gas media

📌 Technical Note

The BB 1 and BB 2 Series differ mainly in terms of body material, pressure class, and gasket options. Consult the GESTRA datasheet or contact us for precise model selection.

Русский

Русский Türkçe

Türkçe