Follow Us on Social Media!

To closely follow our engineering content, product development processes and technical updates on low NOx modulating gas burner technology, you can visit our social media channels. For the latest announcements, please visit our LinkedIn page, watch detailed technical videos on YouTube, follow our field activities and short briefings on Instagram, and access our community content on Facebook.

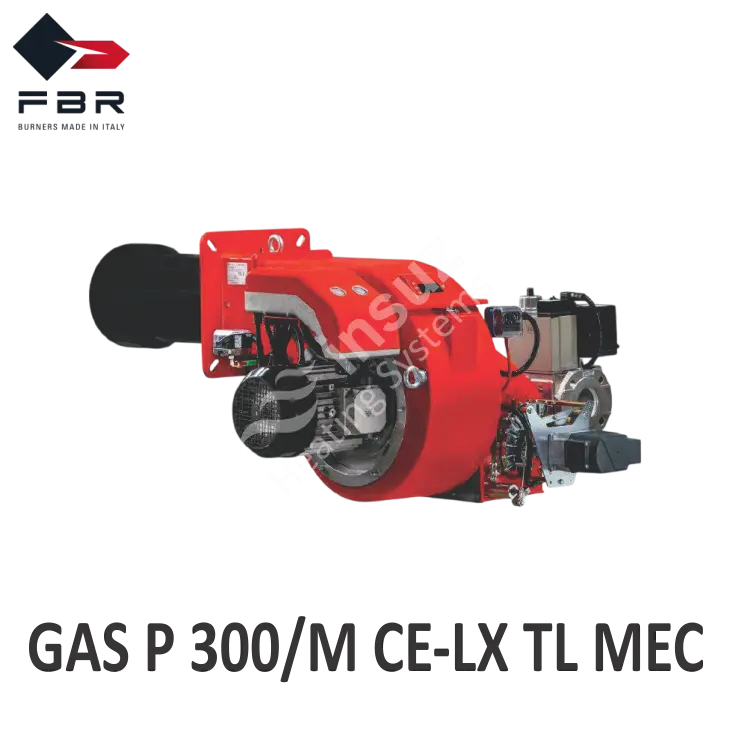

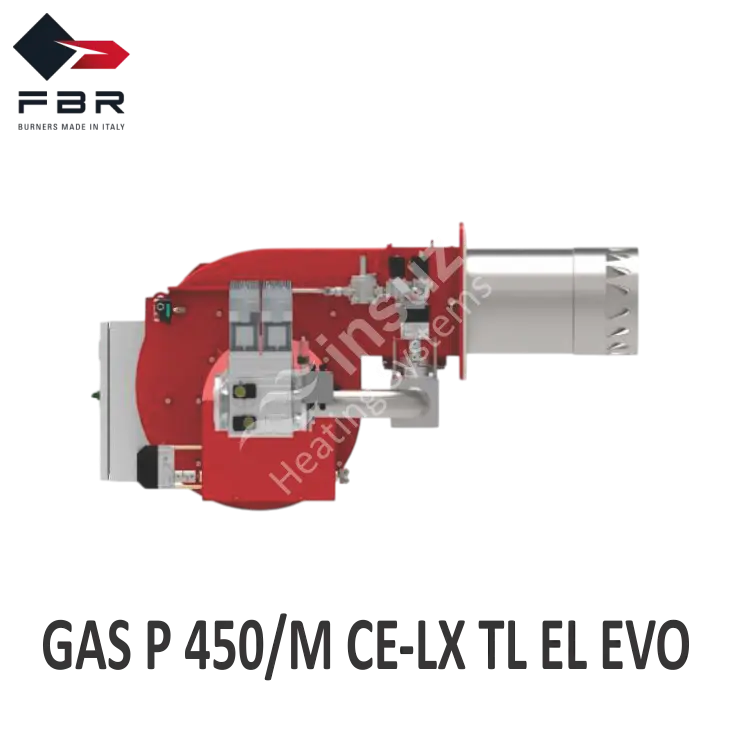

FBR Modulating Gas Low Nox Burner

Low NOx modulating gas burners are high-efficiency combustion devices with modulation capability, designed to minimize NOx emissions in industrial heating and process applications. These burners provide stable flame structure, high energy efficiency and advanced control functions under frequently changing heat load conditions, making them the preferred choice in modern industrial facilities.

Thanks to proportional control, air and gas flow rates are continuously optimized, ensuring both low NOx and high combustion efficiency. They play a critical role in meeting low emission requirements in many systems such as industrial boilers, heat exchangers and process heaters.

Low NOX Modulating Gas Burner – Operating Principle

Low NOx modulating gas burners operate with a digital control system that continuously modulates the gas and air quantities supplied to the combustion chamber according to load demand. Through this modulation, flame temperature is reduced, excess oxygen is precisely adjusted and NOx formation mechanisms are kept under control.

- Modulating valve system: Fuel flow can be adjusted continuously between 0% and 100%.

- Air/gas ratio control unit: The mixture ratio is monitored by real-time sensors and kept at the optimum level.

- Low flame temperature management: Flame temperature is reduced to decrease thermal NOx formation.

- Premix or nozzle-mix technology: Used to increase combustion efficiency and reduce emissions.

This control system can respond quickly to continuously changing load demands in hot water boilers, steam boilers or heat-exchanger-based processes. For example, when working together with a high-efficiency hot water boiler or a steam boiler, it further increases energy savings.

FBR Modulating Gas Low Nox Burner Technical Features

- Full modulation capability between 0% and 100%

- Low NOx levels compliant with EN 676 and ErP

- High-efficiency premix or nozzle-mix combustion technology

- Digital combustion control panel with advanced PID algorithms

- Flame sensors, pressure switches and multi-level safety equipment

- Low maintenance requirement and long service life

- Stable combustion structure with low noise level

Low NOX Modulating Gas Burner Design Criteria

The following engineering criteria are considered in burner design to minimize NOx values:

- Combustion chamber dimensions and flame geometry

- Aerodynamic design of air inlet channels

- Turbulence and mixture homogeneity in the premix chamber

- Thermal resistance of the burner head

- Backpressure tolerance and chimney draft characteristics

- Linear control capability of air/gas ratio valves

Low NOX Modulating Gas Burner – Advantages

- Full compliance with NOx emission regulations

- Lower operating costs and 5–15% fuel savings

- High combustion stability and precise temperature control

- Low flue gas losses

- Long service life and low maintenance requirement

- High energy efficiency thanks to a wide modulation range

Low NOX Modulating Gas Burner – Comparison with Other Burner Types

Low NOx modulating gas burners offer significant advantages compared to different burner types:

- Compared to two-stage burners: Lower emissions, more stable flame and fewer on/off cycles.

- Compared to atmospheric burners: Higher control accuracy and more efficient combustion.

- In high-capacity industrial systems: Higher energy savings and better process adaptability.

In addition, low NOx burners enable high efficiency in heat-exchanger-based processes. For example, when used together with a plate heat exchanger or a tube and shell heat exchanger, they increase the stability of the heat transfer process.

Low NOX Modulating Gas Burner – Application Areas

Low NOX Modulating Gas Burner – Automotive Industry

In automotive production lines, low NOx burners are widely used in heat-treatment furnaces, paint-drying tunnels and hot water/steam generation systems. Because they can respond quickly to continuously changing process loads, energy consumption is optimized.

Low NOX Modulating Gas Burner – Energy Sector

They are preferred in energy plants, auxiliary boilers, process heaters and district heating systems due to low emission requirements. They provide high efficiency, especially in boilers that require low NOx performance. In coal-fired systems, a pulverized coal burner can be considered as an alternative solution.

Low NOX Modulating Gas Burner – Construction Sector

In the construction industry, low NOx modulating gas burners are preferred to meet environmental requirements in large-capacity hot water boilers, central heating systems and drying furnaces.

Low NOX Modulating Gas Burner – Food and Beverage Industry

They are used in applications such as pasteurization, sterilization, steam production and process heating. Stable and clean combustion provides a major advantage due to hygienic environment requirements.

Low NOX Modulating Gas Burner – Chemical and Petrochemical

They are chosen to meet NOx limitations in process reactors, heat exchangers and high-temperature processes. Continuous modulation allows process temperature to be controlled with high precision.

Low NOX Modulating Gas Burner – Importance of Low NOX

Low NOx modulating gas burners are of critical importance in industrial plants in terms of both energy efficiency and emission standards. With their modulation capability, low NOx performance, compatibility with modern control systems and high operating stability, they provide a reliable solution across many different sectors. In addition, when integrated with hot water boilers, steam boilers and various heat exchanger systems, overall process efficiency is further improved. For projects focused on clean combustion and energy saving, selecting an FBR Modulating Gas Low Nox Burner offers a strong technical and environmental advantage.

Русский

Русский Türkçe

Türkçe