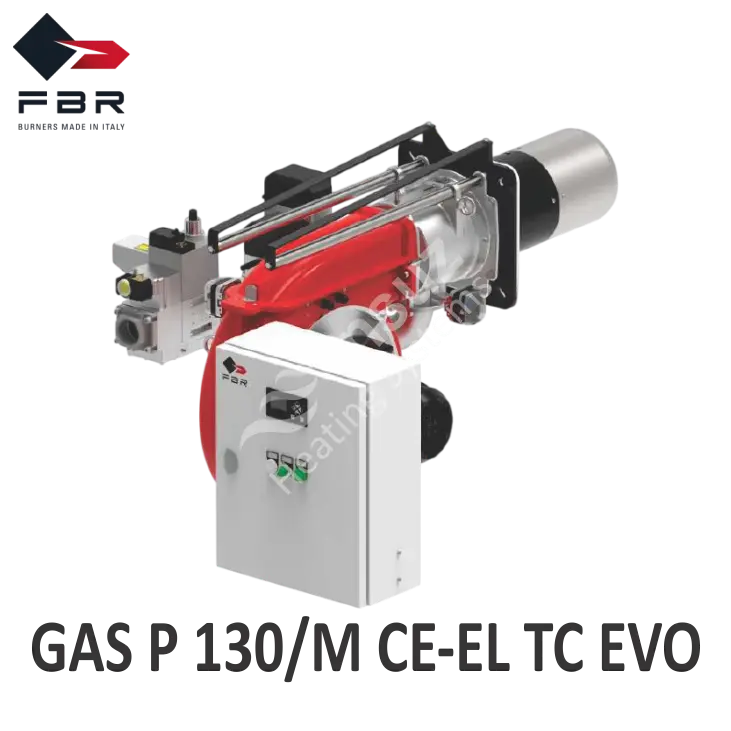

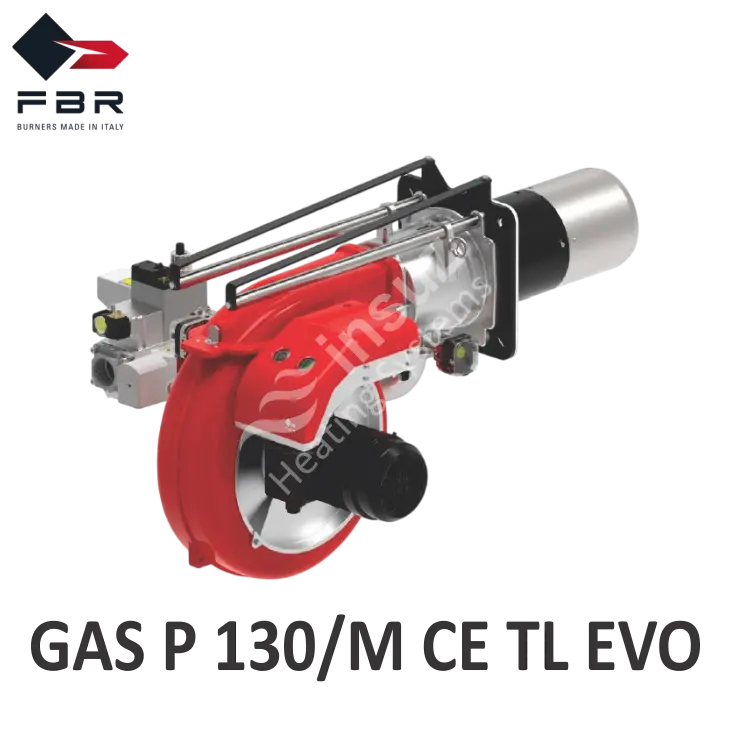

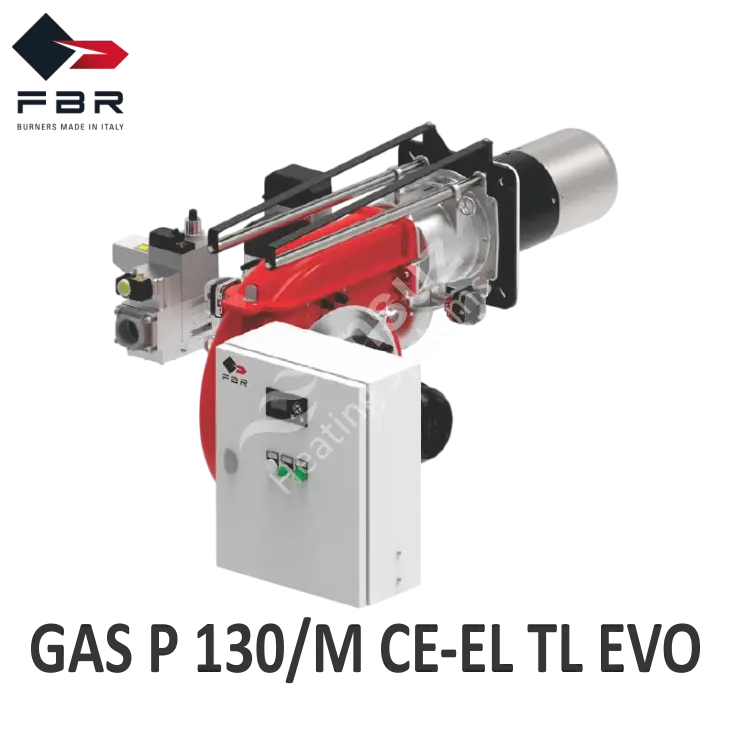

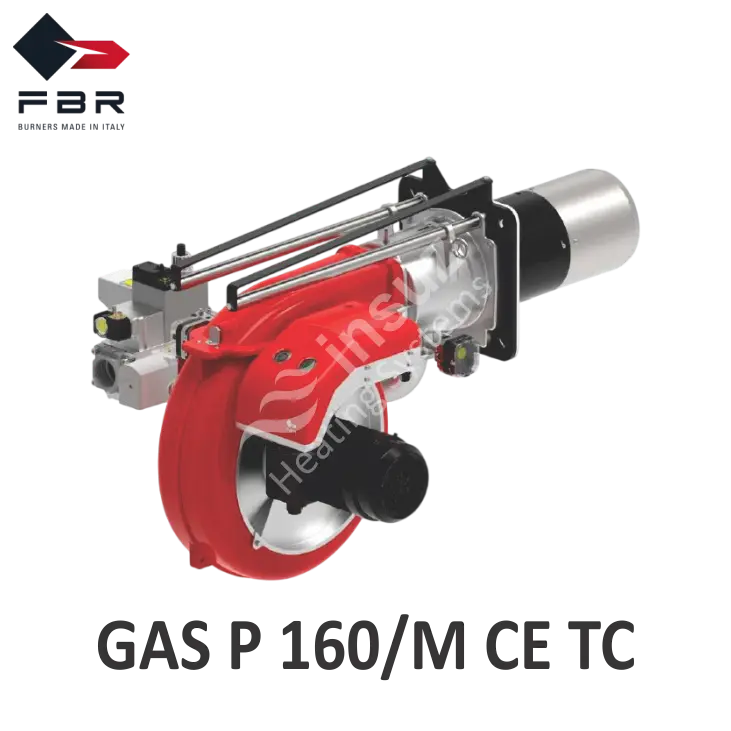

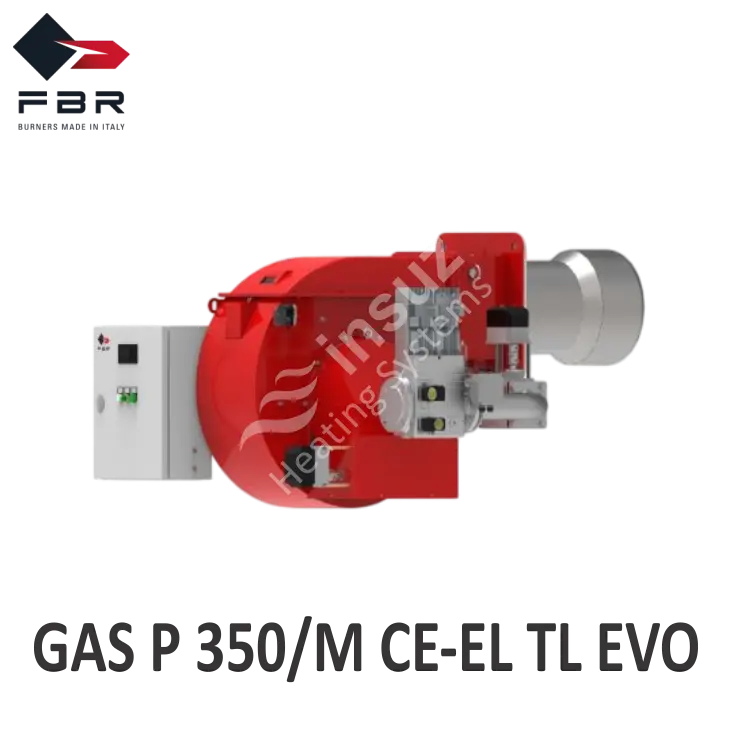

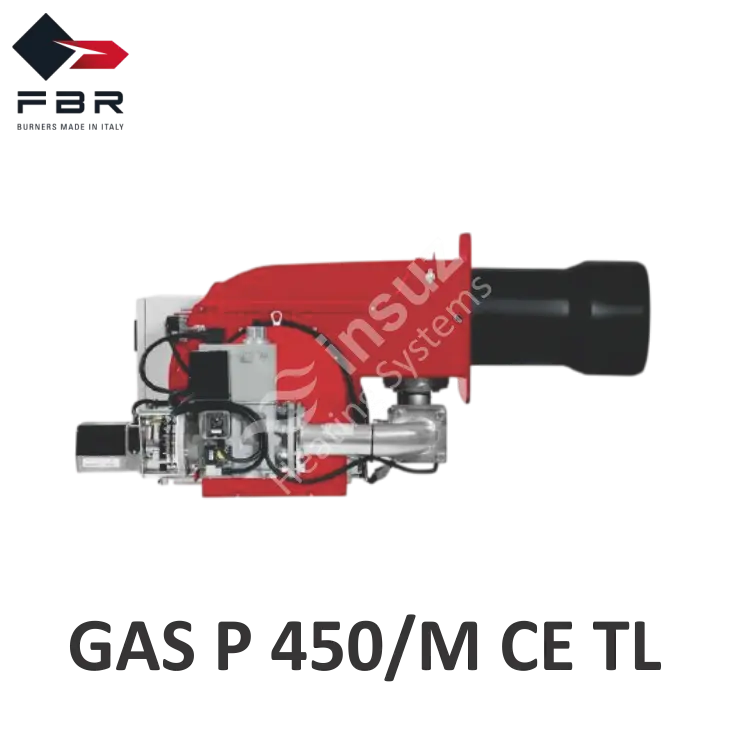

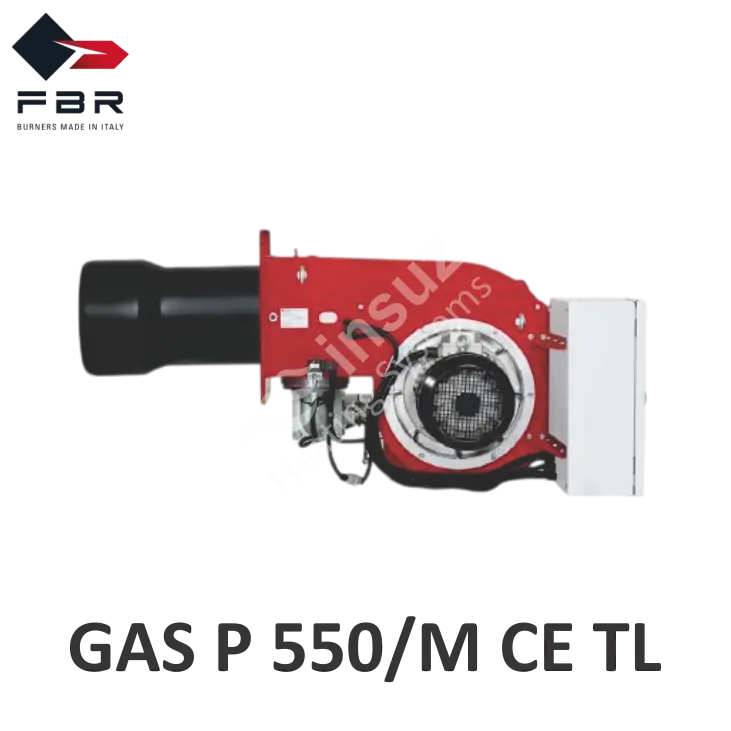

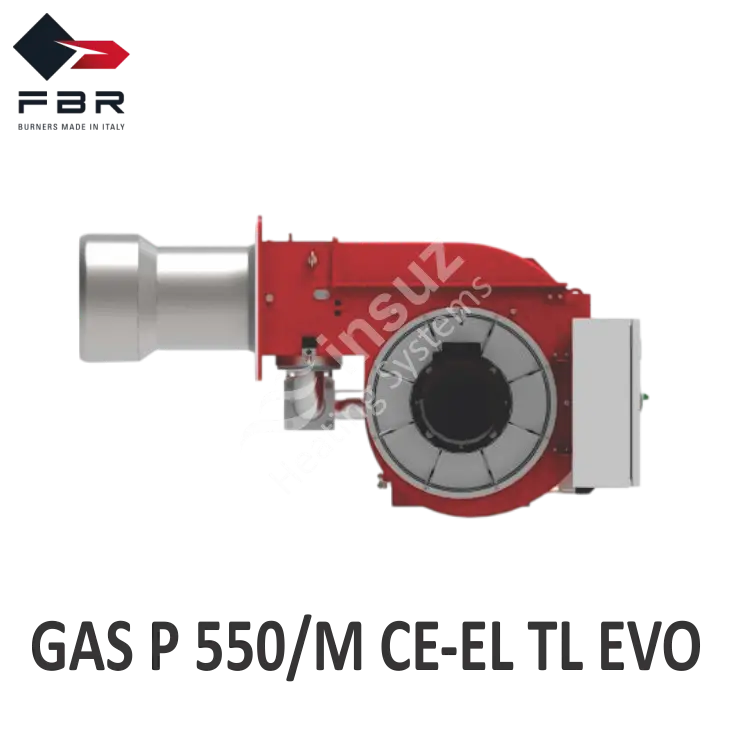

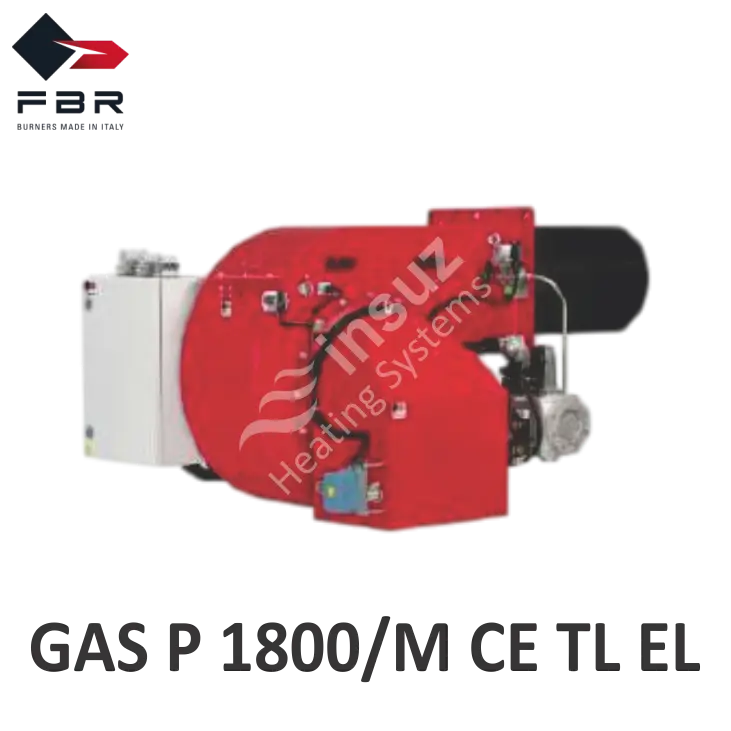

What is FBR Modulating Gas Burner?

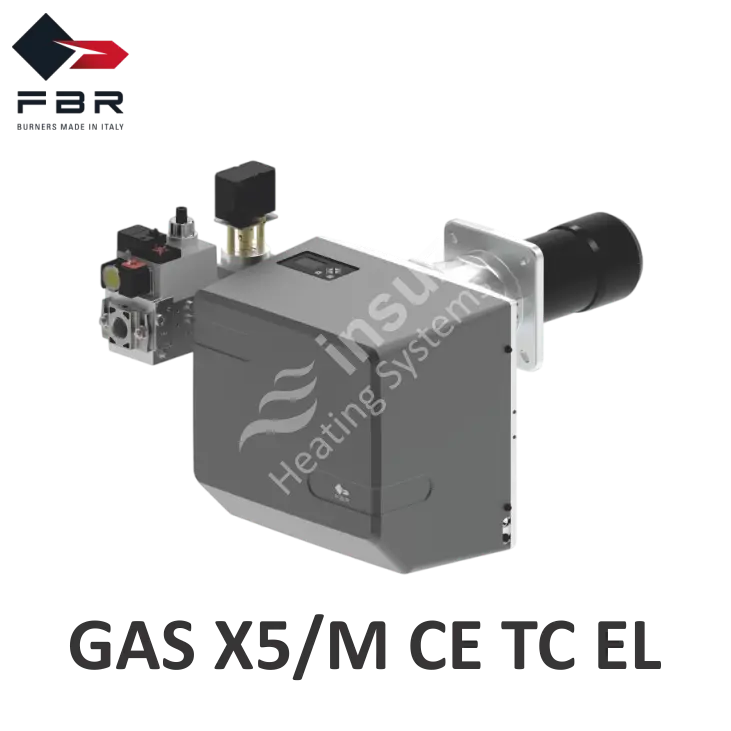

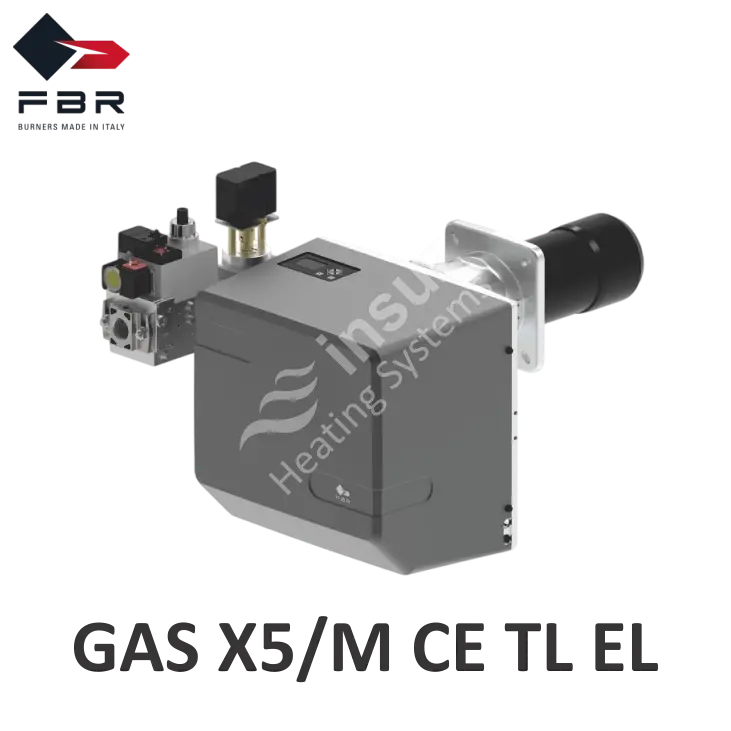

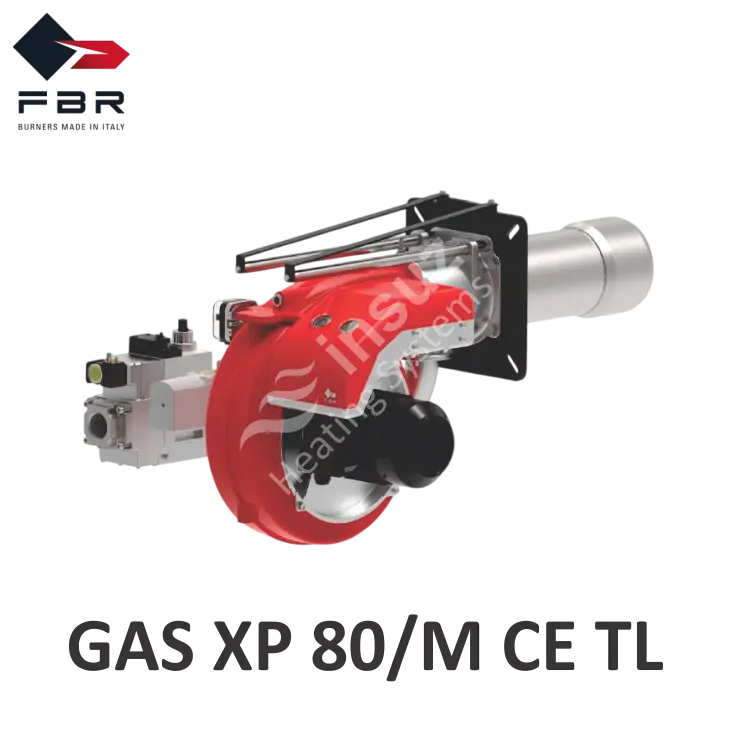

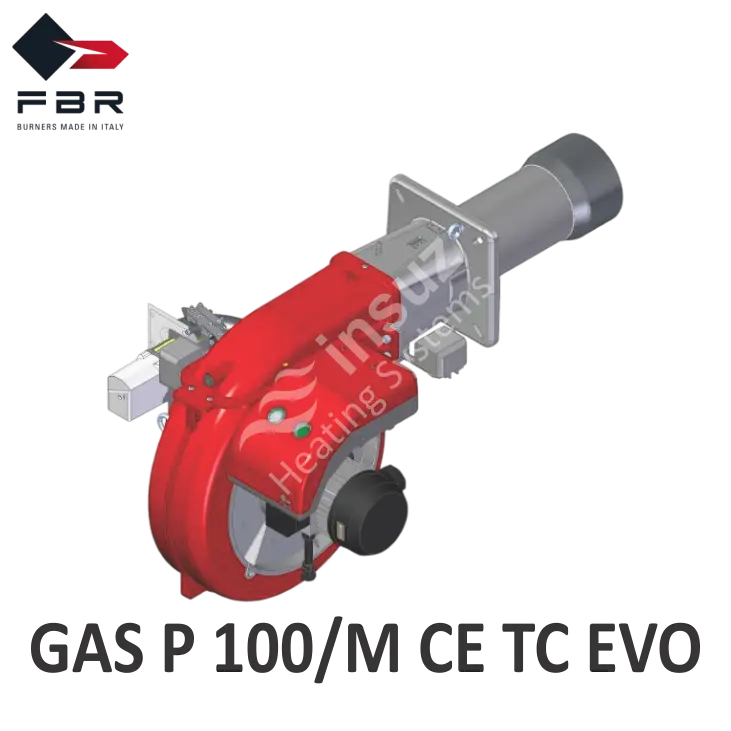

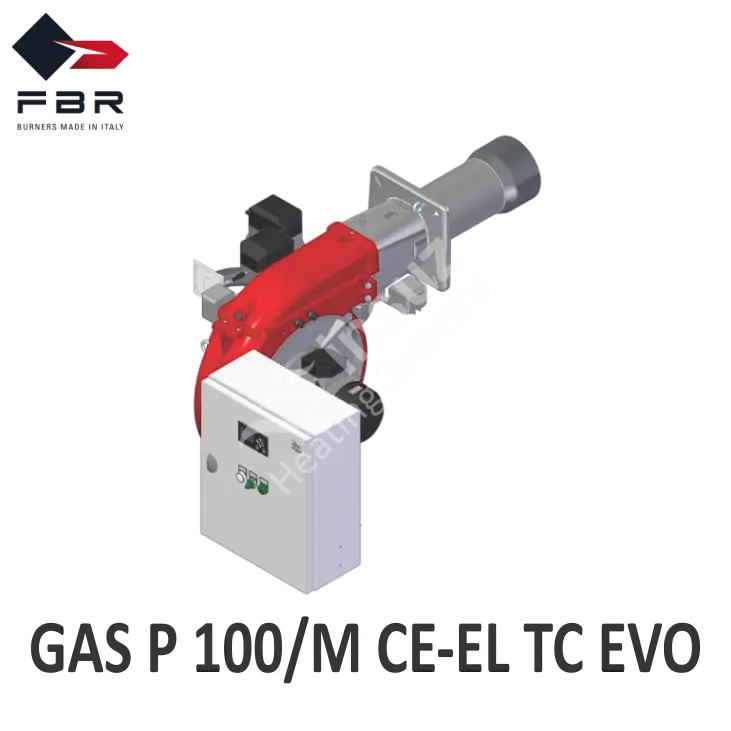

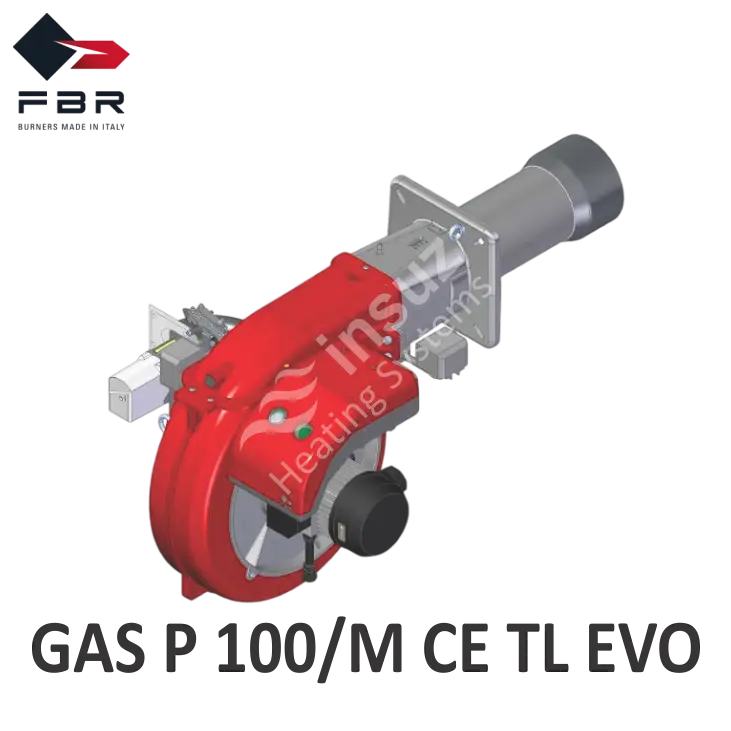

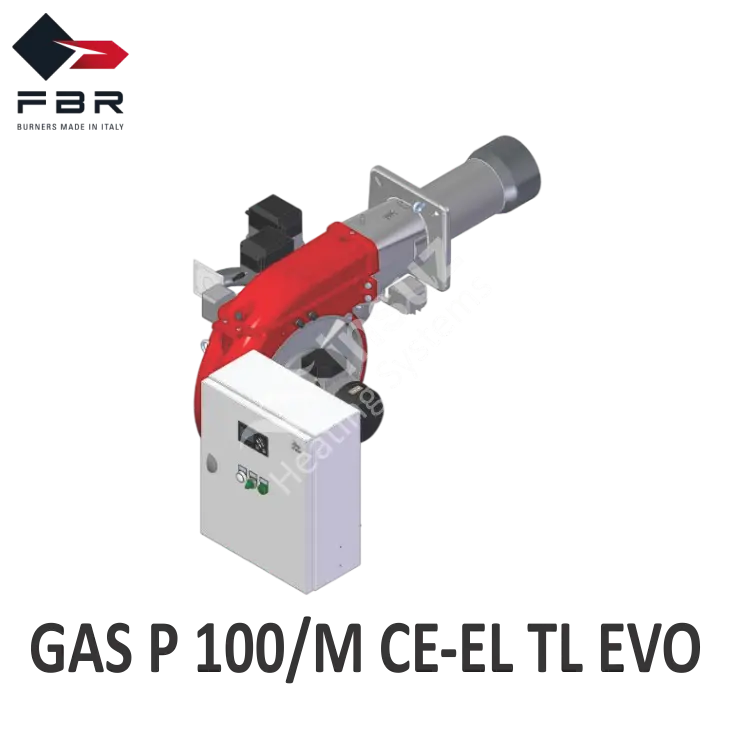

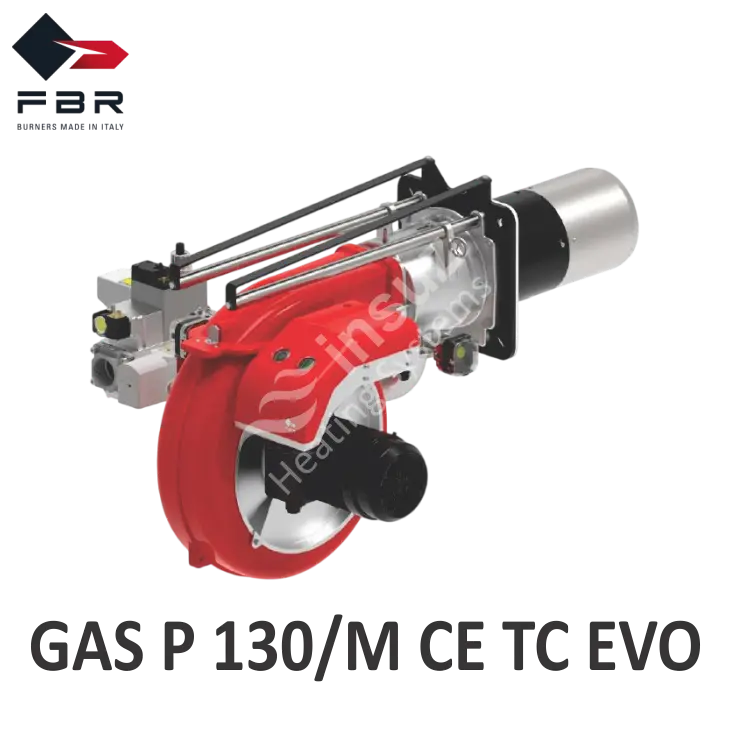

The FBR Modulating Gas Burner is equipped with an advanced control technology capable of adjusting combustion performance continuously and steplessly according to process load demand. This structure increases energy efficiency while keeping emission values at levels compliant with international regulations. The system delivers high stability and low fuel consumption in applications with hot water boilers, high temperature hot water boilers and steam boilers.

Operating Principle of FBR Modulating Gas Burner

In this control architecture, servo motors manage the gas valve and combustion air damper in a synchronized manner. The air–gas ratio is kept at an optimum level across the entire load range. High-precision modulation capability ensures more stable heat transfer on heating circuits and heat exchangers. In this way, process temperature is managed within narrow tolerances in both plate heat exchanger and tube and shell heat exchanger systems.

Engineering Advantages of FBR Modulating Gas Burner

Energy Efficiency and Emission Control

Thanks to continuous modulation capability, unnecessary fuel consumption is prevented. As combustion quality improves, NOx, CO and unburned hydrocarbon values drop to minimum levels. This provides a strategic advantage both in terms of compliance with environmental regulations and reduction of operating expenses.

Thermal Stability and Equipment Lifetime

Stepless management of load fluctuations reduces potential thermal shocks in the boiler. Increased process stability significantly extends component lifetime, especially in high-capacity plants.

Technical Comparison of FBR Modulating Gas Burner with Other Burner Systems

While single-stage burners can only operate at full capacity, two-stage systems offer two distinct load levels. However, the FBR Modulating Gas Burner provides continuous and linear control over a wide load range and optimizes the energy balance at the highest engineering standard. When operated together with a pulverized coal burner in plants using pulverized fuel, load balancing processes become more stable and reliable.

Professional Solution Approach for FBR Modulating Gas Burner

İnsuz Heating Systems designs modulation technology in an integrated manner with industrial heat generation equipment. From steam generation systems to heat exchangers, it delivers high-efficiency and long-lasting solutions across all lines in full compliance with engineering standards.

Follow Our YouTube Channel

To watch technical test videos, field applications and engineering content related to FBR modulating gas burners, you can follow the İnsuz Heating Systems YouTube channel.

Русский

Русский Türkçe

Türkçe