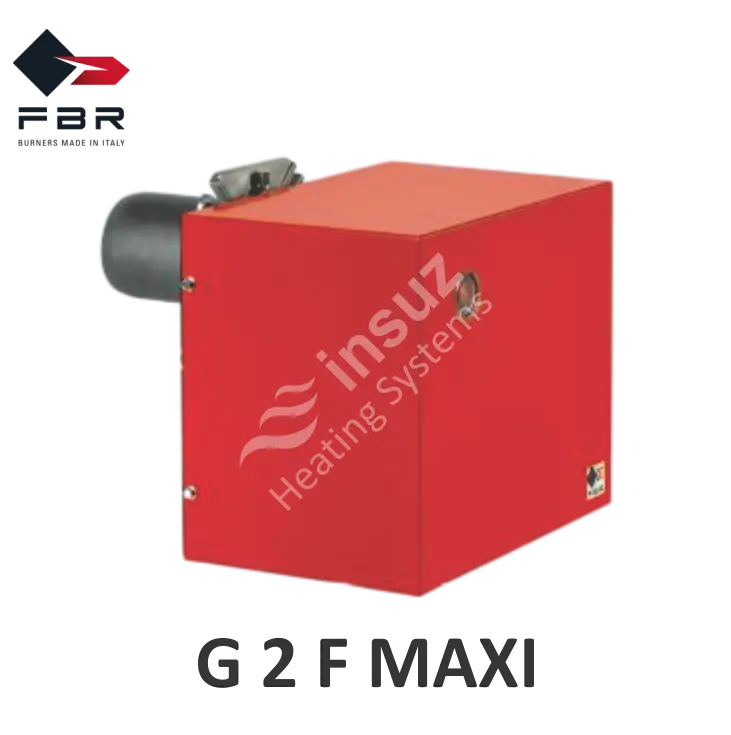

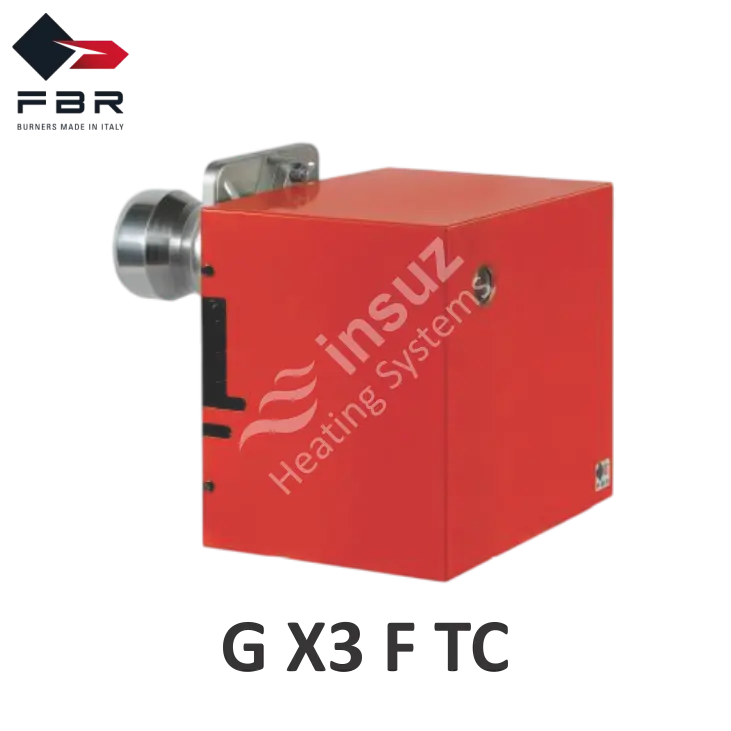

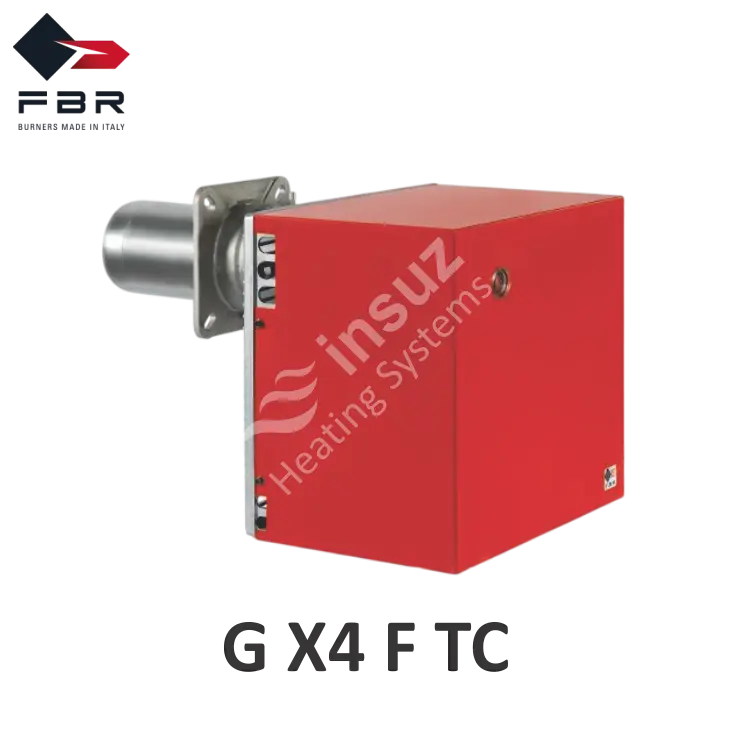

FBR Burners for Bakery Ovens

FBR burner systems for bakery ovens offer durable and cost-effective solutions powered by diesel fuel. Designed to meet industrial needs, they ensure high efficiency and long-lasting performance across a variety of applications such as food ovens, pastry ovens, bread ovens, bagel ovens, and pizza ovens.

For customized solutions to meet your specific requirements, feel free to contact us, and visit our YouTube channel to explore our other products.

Choose Reliable FBR Burners for Bakery Ovens for Food Applications

Technical Excellence of Burners for Bakery Ovens

FBR burner systems for bakery ovens ensure stable performance in food production processes through precise combustion control and high efficiency. diesel ,light oil powered design and most advanced solutions among all diesel burners.

Italian Quality in Burners for Bakery Ovens

Manufactured with proven Italian engineering, FBR burners guarantee exceptional quality for bread ovens, bagel ovens, pastry ovens, and pizza ovens with their durable and long-lasting design.

Durable and Economical Solution for Bakery Ovens

Developed for demanding production conditions, these burners minimize operating costs thanks to low maintenance requirements and high energy savings. Equipped with Low NOx technology, they provide an eco-friendly, economical, and reliable solution.

Easy Integration for Bakery Ovens

With their Single Stage options, FBR burners can be easily integrated into different types of ovens, enabling safe use without additional investment in existing systems.

High Safety Standards for Bakery Ovens

Advanced safety sensors and automatic control systems ensure maximum safety during production, a critical feature for continuous food industry operations.

Energy Efficiency for Bakery Ovens

Optimized combustion technology for diesel consumption enhances energy efficiency, increasing business competitiveness. Among all diesel burners, FBR stands out for its exceptional efficiency and reliability.

Русский

Русский Türkçe

Türkçe