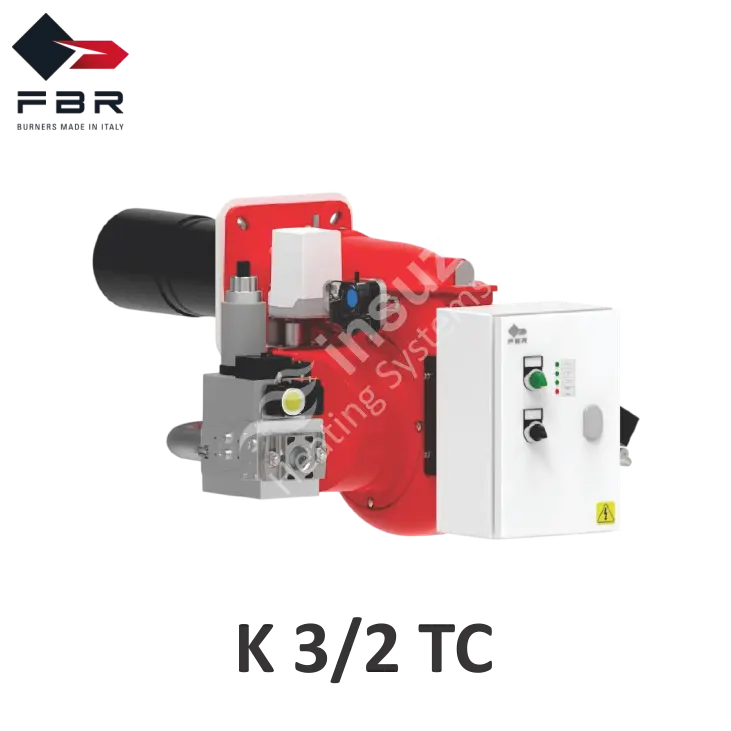

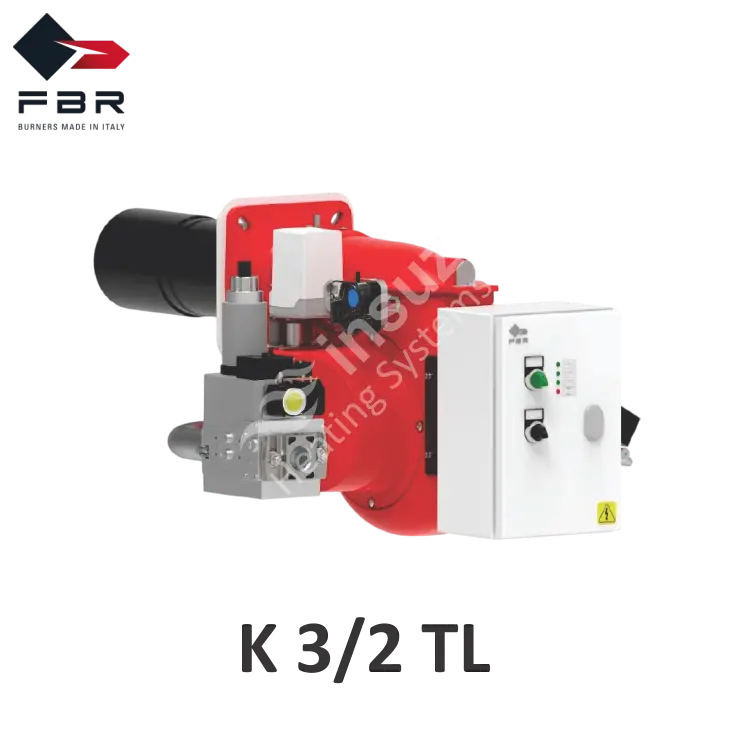

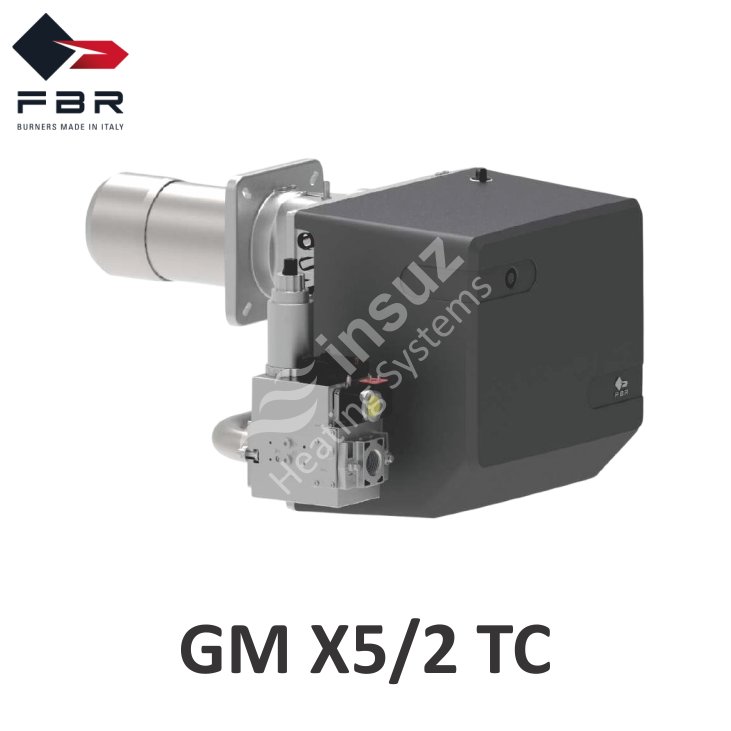

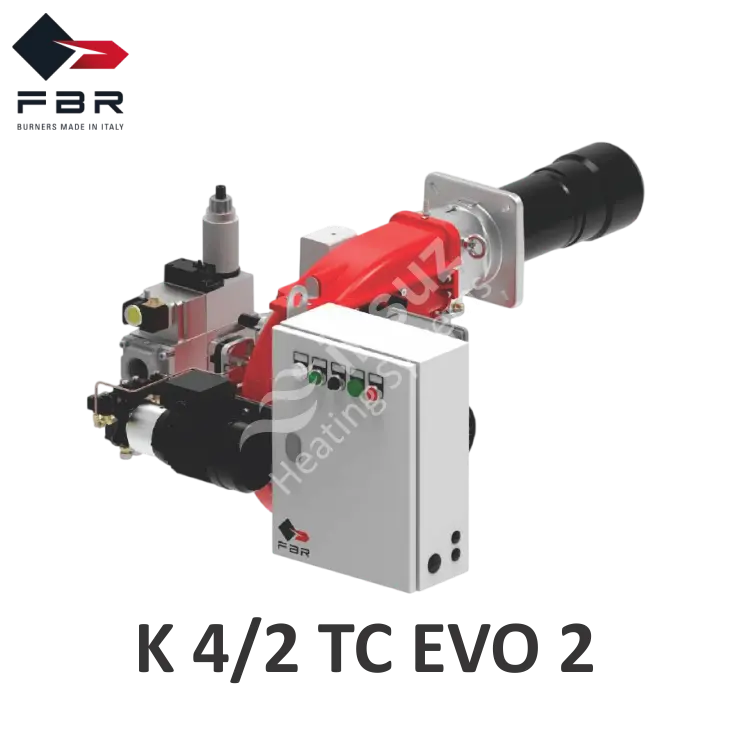

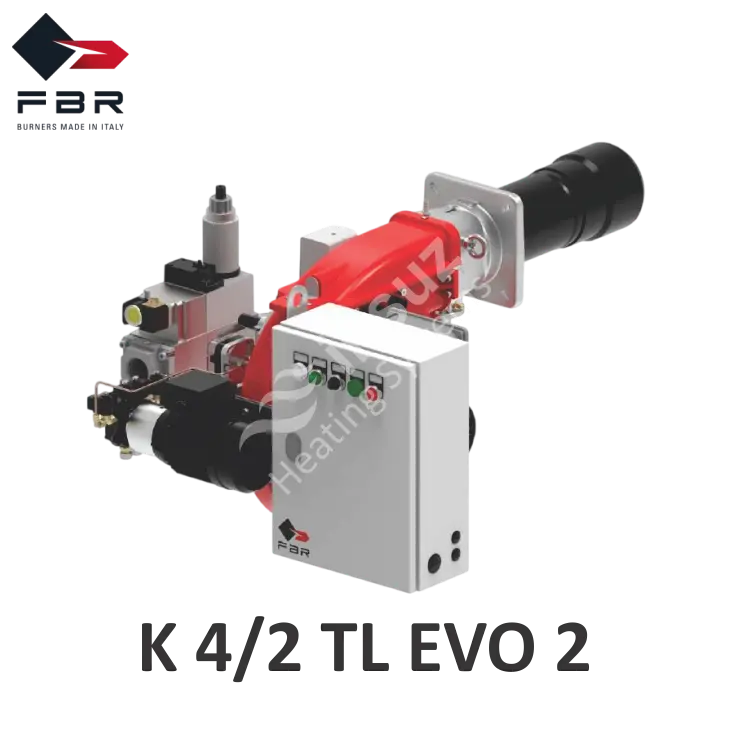

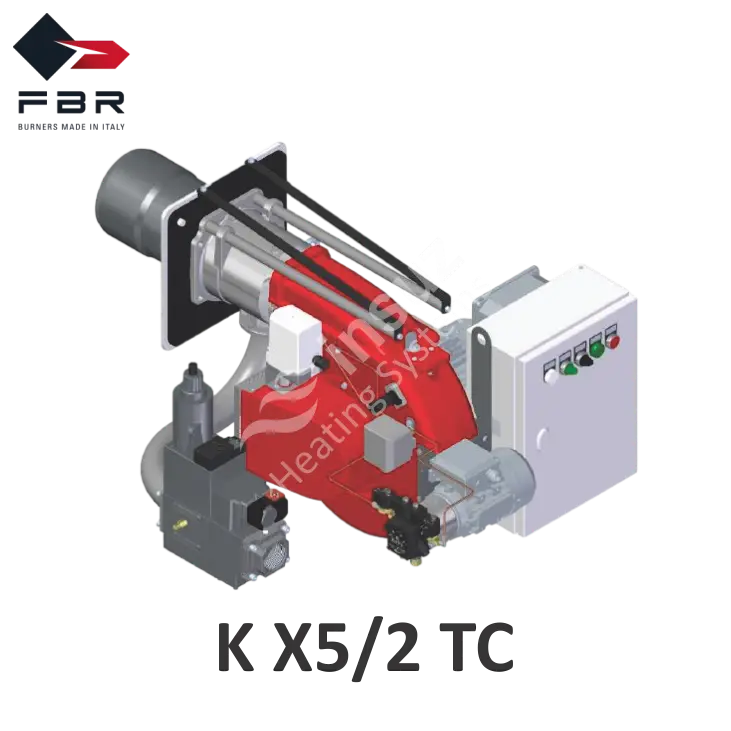

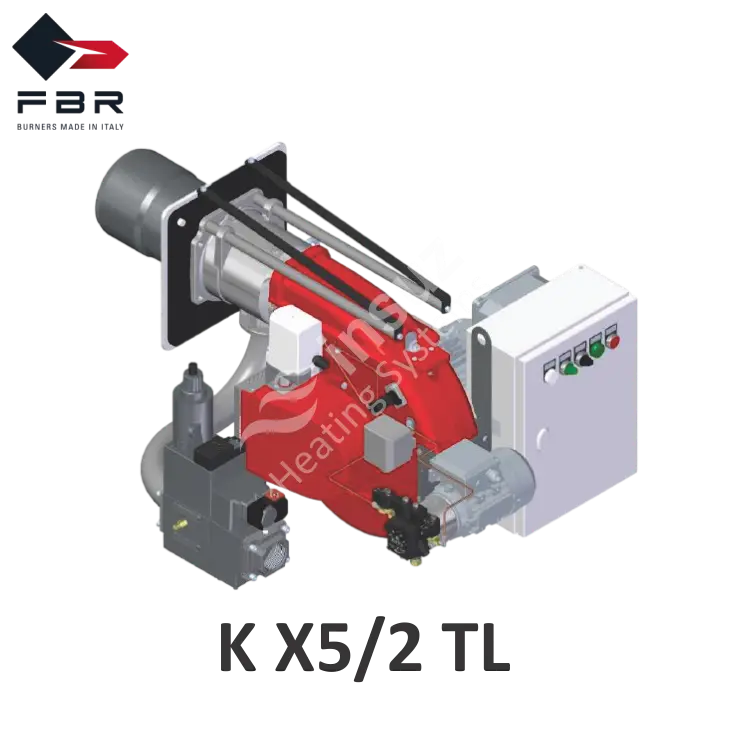

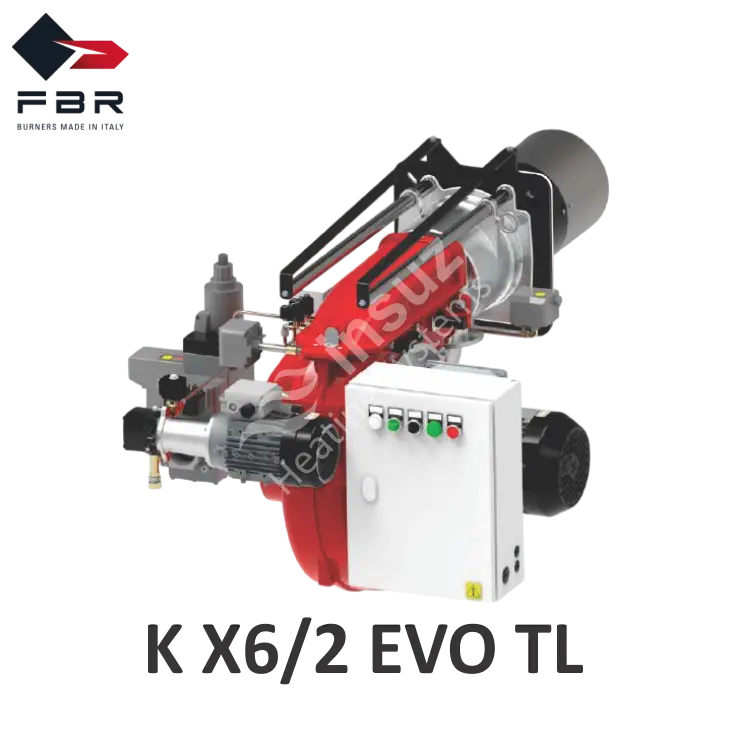

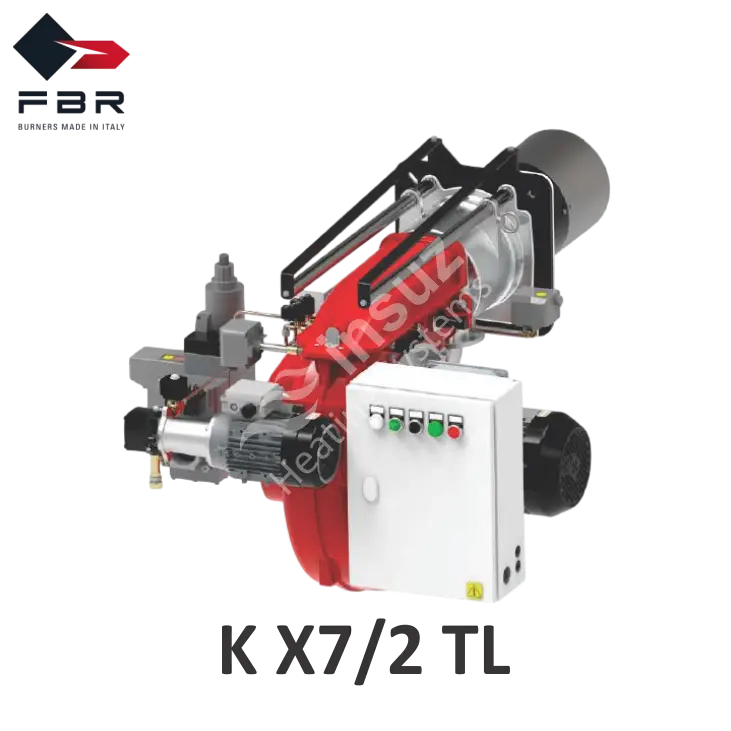

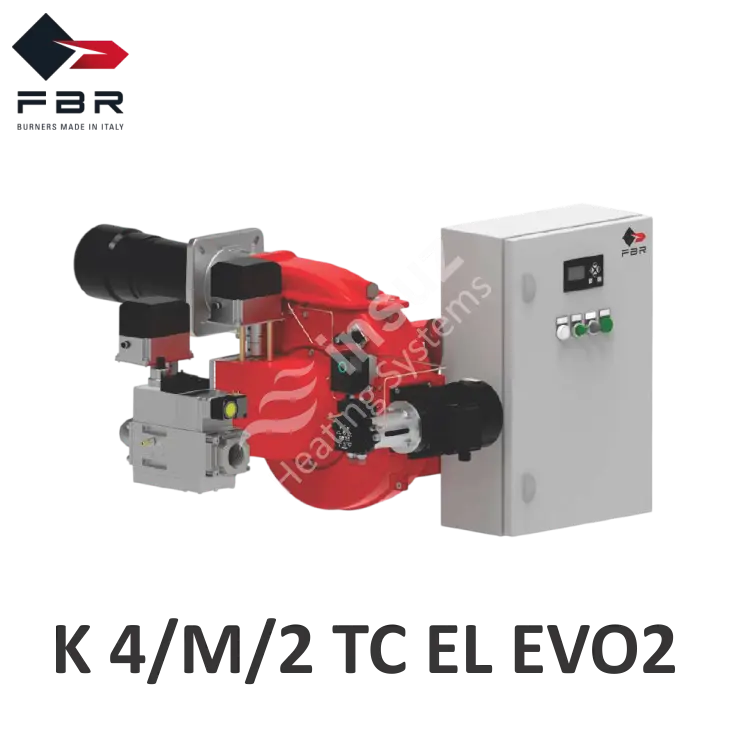

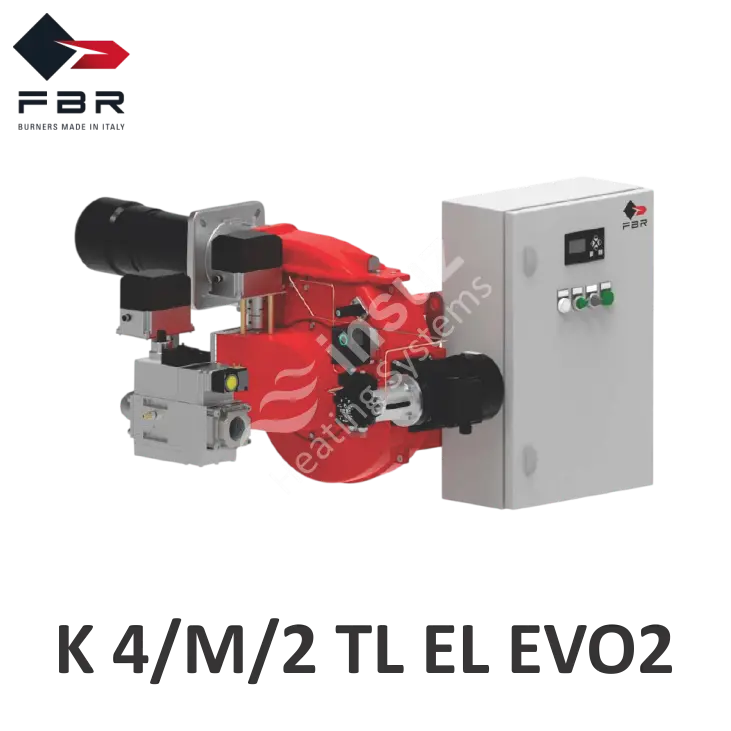

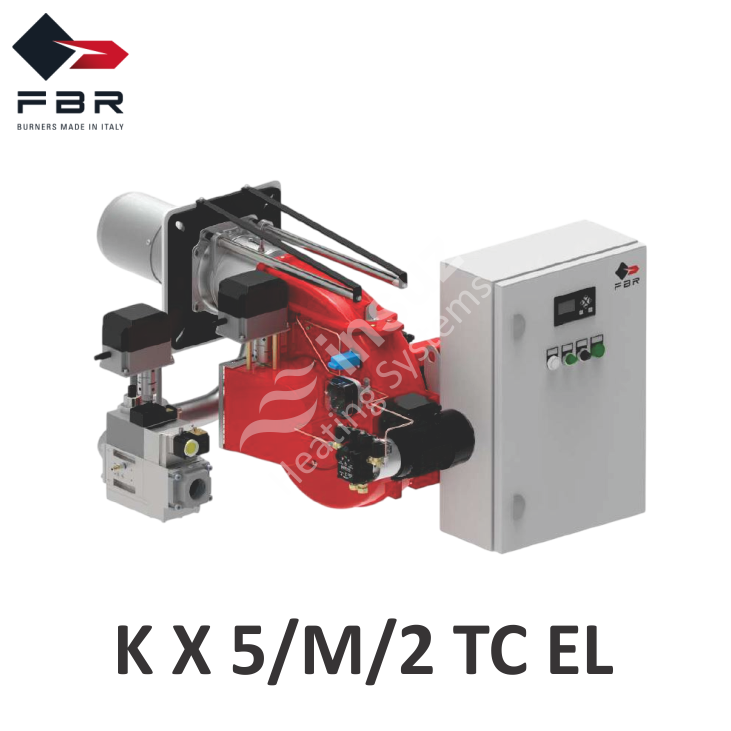

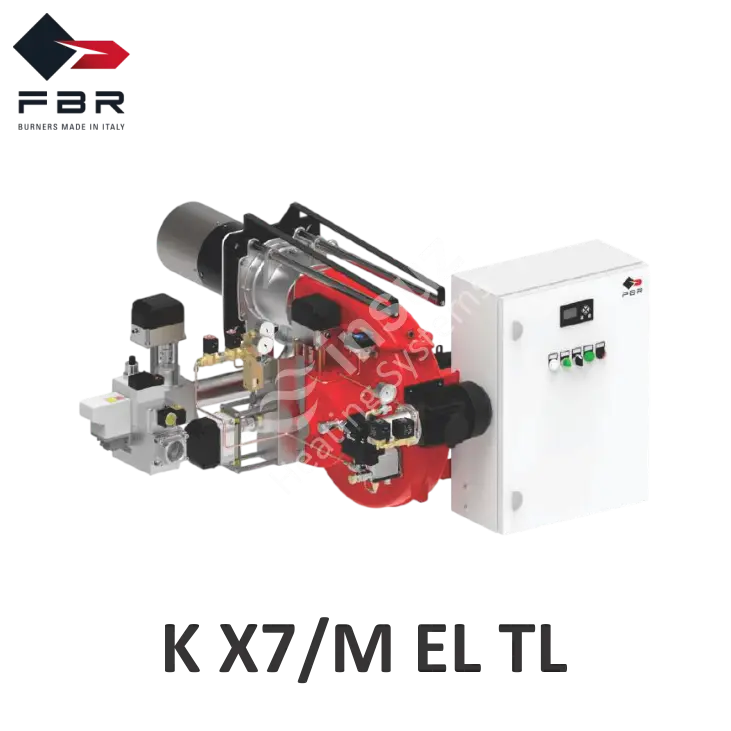

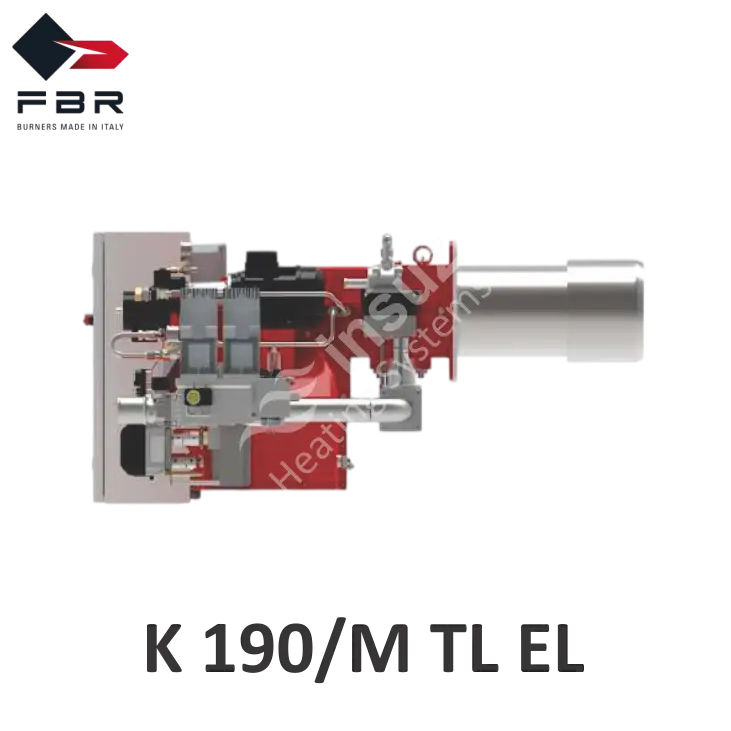

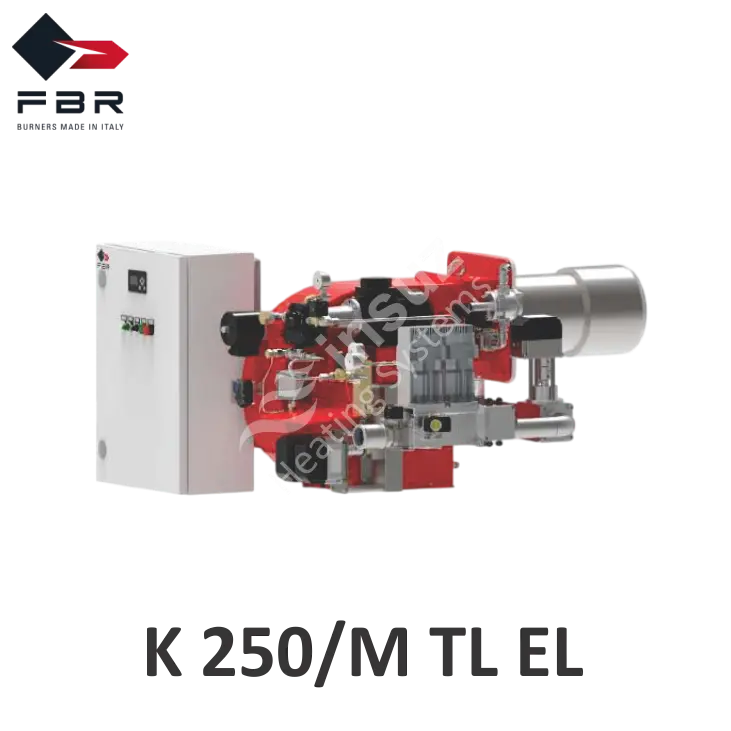

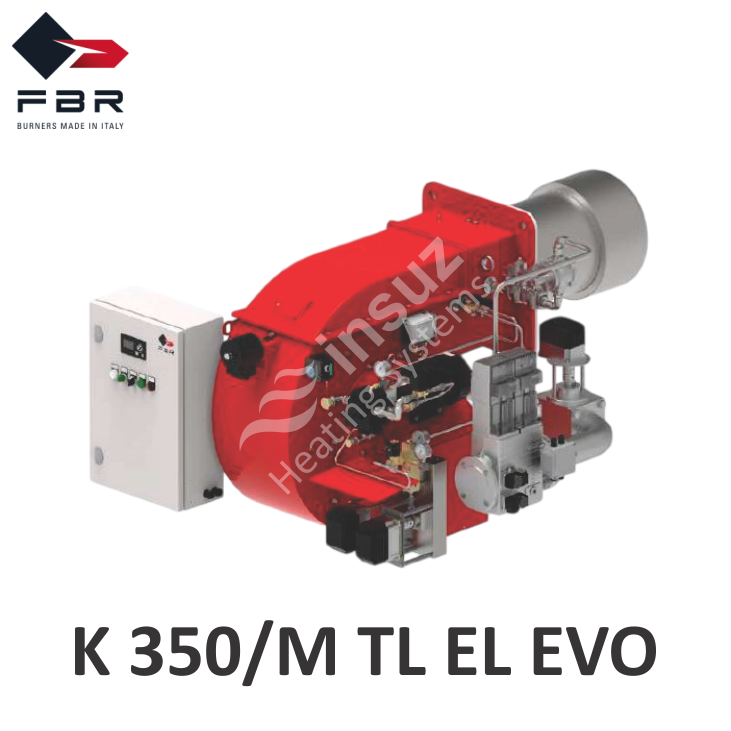

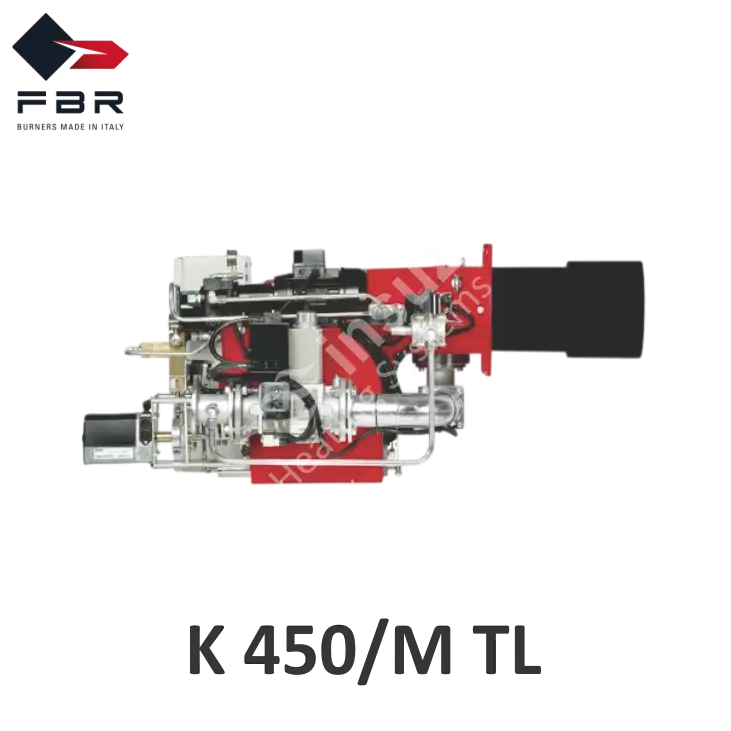

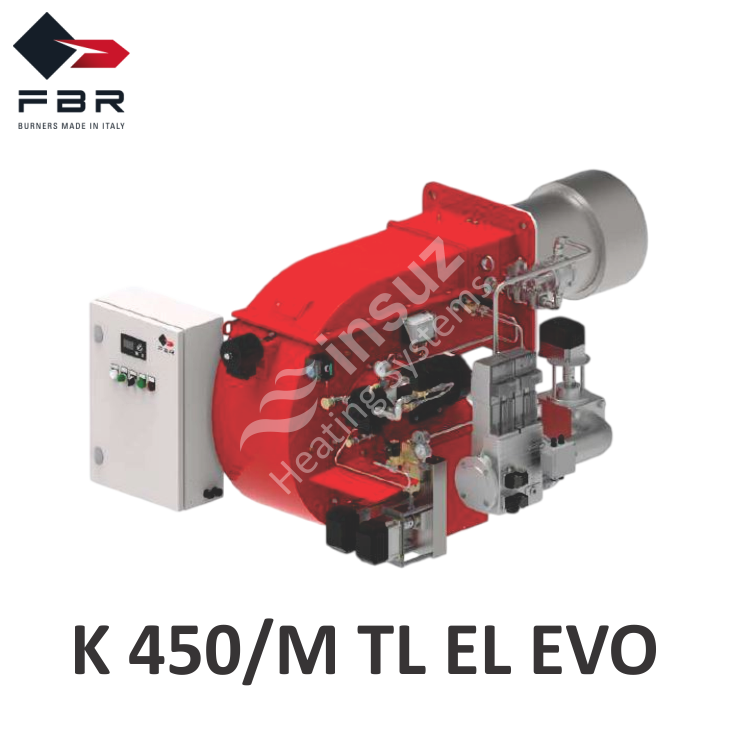

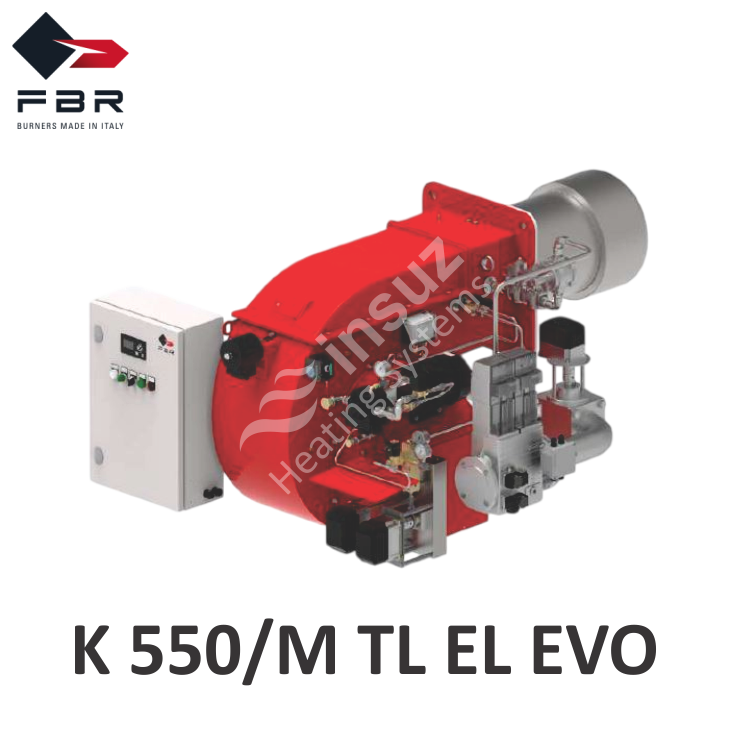

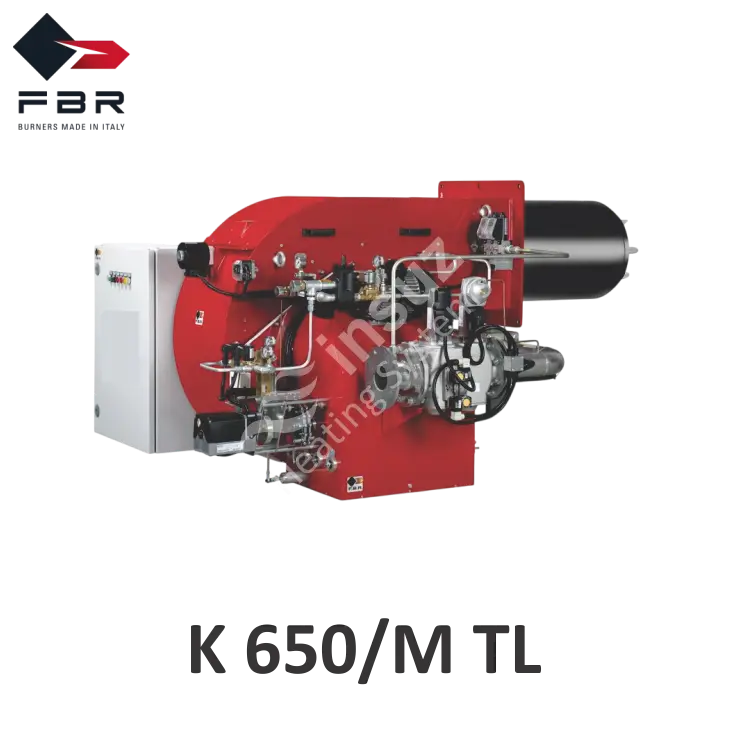

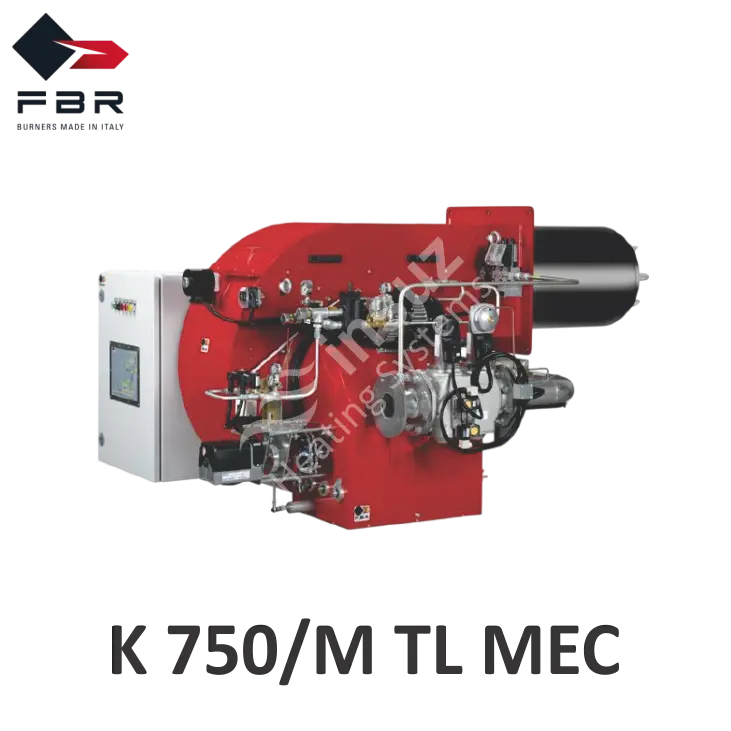

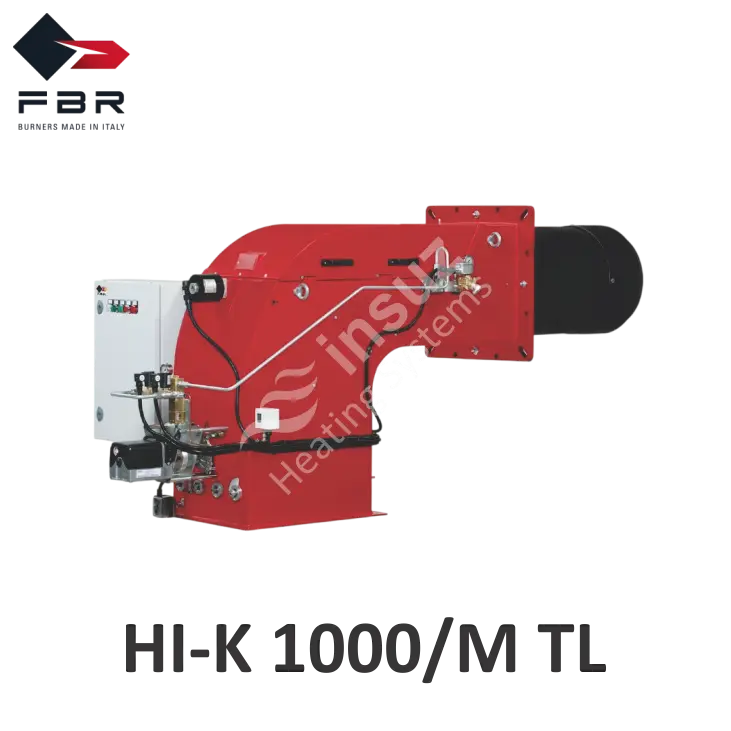

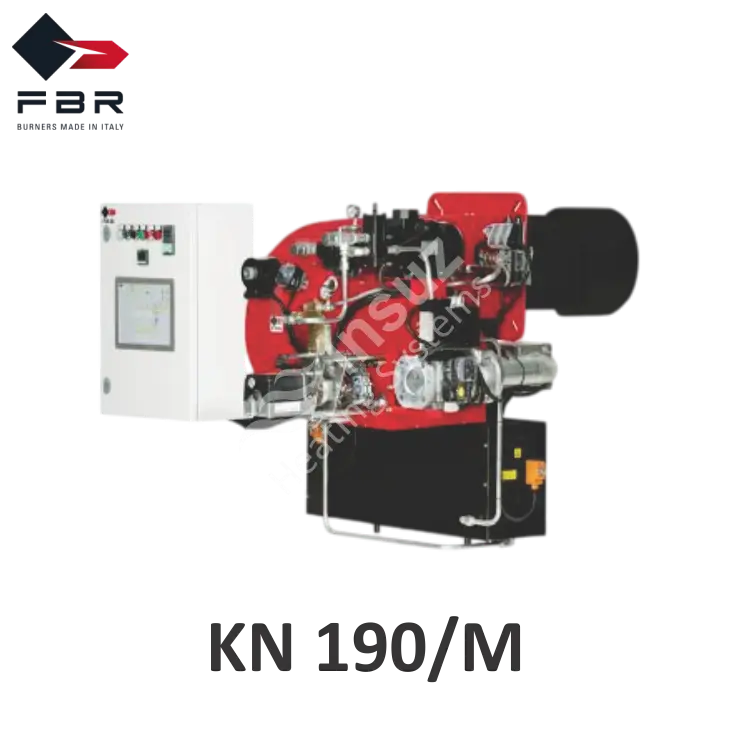

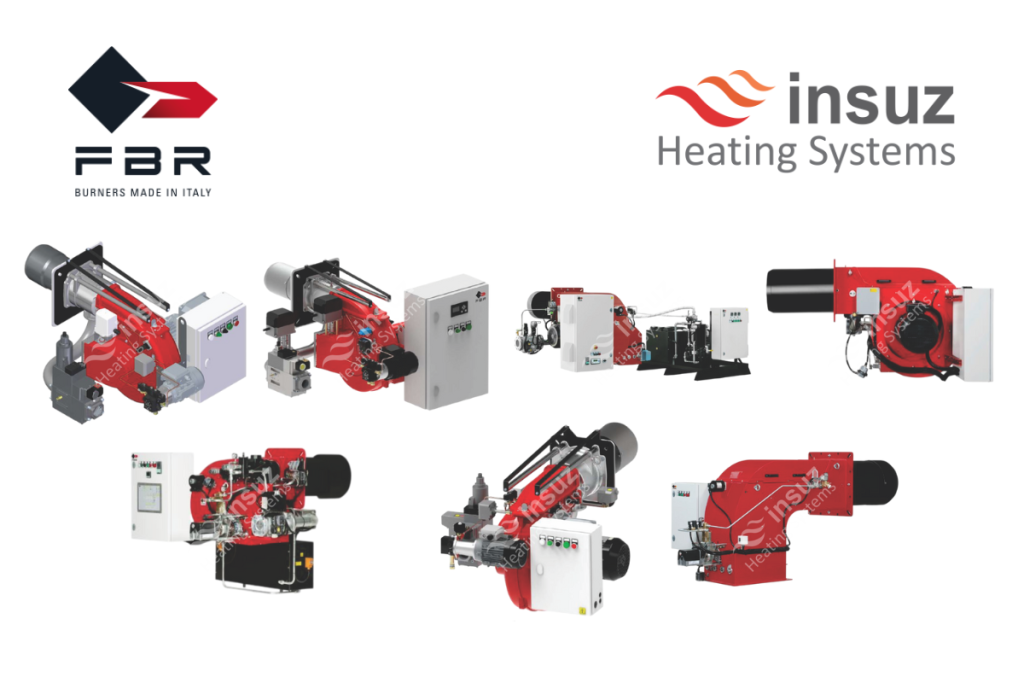

FBR Burner Models

Offer solutions that deliver high efficiency and reliability in industrial heating systems. Thanks to a wide product range, you can achieve the desired performance for different requirements with gas, diesel, fuel oil and dual-fuel options.

Follow our YouTube channel for other Insuz products

Dual Fuel Burner Introduction and Basic Concepts

Dual Fuel Burner technology is an advanced combustion solution developed to provide energy efficiency, fuel flexibility and operational continuity in industrial heating processes. These burners are capable of operating with two different fuel types (typically natural gas–fuel oil or natural gas–diesel) on the same system. Fuel changeover can be carried out via manual or automatic control modules, providing a significant safety margin for operators in the event of energy supply interruptions.

When evaluated in terms of key parameters such as combustion efficiency, emission levels, safety standards, maintenance requirements and operating costs, Dual Fuel Burner systems have become indispensable components of modern industry. This article presents a comprehensive engineering-oriented assessment of Dual Fuel Burners.

Dual Fuel Burner Operating Principle

The operating principle of Dual Fuel Burners is based on burning two different fuel sources in the same combustion chamber with an optimum air–fuel mixture under controlled conditions. During fuel changeover, combustion chamber pressure, flow rate, air entrainment coefficient and mixture ratios are readjusted by the automation system. For this reason, the system requires a high level of sensor feedback and control algorithms.

- Fuel Modulation: During fuel changeover, flow regulation and atomization parameters are re-optimized according to the fuel in use.

- Air–Fuel Mixture: Different fuel types require different oxidation characteristics on the air side. The system improves combustion efficiency by using feedback from oxygen sensors.

- Safety Equipment: Flame monitoring relays, solenoid valves and safety sensors play a critical role during fuel transition.

Dual Fuel Burner Technical Features

Dual Fuel Burners developed for industrial processes stand out with technical parameters such as high temperature resistance, modulation control, fast start/stop capability and low maintenance requirements.

- Multi-stage or modulating control

- Optimized mixing geometry for high combustion efficiency

- Burner head designs that support low NOx emissions

- Dual-safe fuel line configurations

- Automation systems with digital control panels

Dual Fuel Burner Advantages

The most prominent advantage of Dual Fuel Burner technology is fuel flexibility, which increases operational reliability. In addition, there are many engineering advantages worth noting.

- Fuel Supply Security: In the event of natural gas interruptions, fuel oil or diesel can be brought online so that production continues without stopping.

- Energy Cost Optimization: Provides easy switching to an alternative fuel in periods when fuel unit prices are volatile.

- Low Emissions: Modern designs significantly reduce NOx and CO values.

- High Efficiency: Atomization quality and air-guide geometry keep combustion efficiency consistently high.

- Ease of Maintenance: Combined fuel heads and modular structures shorten service times.

Dual Fuel Burner Design Criteria

When designing a Dual Fuel Burner, many engineering parameters such as combustion chamber pressure, boiler capacity, fuel viscosity, atomization characteristics and control algorithms must be considered.

- Turbulence level in the combustion chamber

- Atomization pressure and spray angle

- Fuel lower heating value and rheological parameters

- Need for oxygen trim control

- Compliance with emission regulations

Dual Fuel Burner Fields of Application

Dual Fuel Burners are widely used to ensure continuity of thermal processes in different industrial sectors.

Dual Fuel Burner Automotive Industry

In automotive plants, high-efficiency combustion solutions are used in paint curing ovens, heat treatment lines and utility boilers. In this context, Dual Fuel Burners operating together with a hot water boiler are particularly preferred for hot water generation.

Dual Fuel Burner Energy Sector

Since uninterrupted burner operation is critical in energy facilities, dual-fuel systems provide an effective solution against natural gas supply interruptions. In plants with high steam demand, they are used in integration with a steam boiler.

Dual Fuel Burner Construction Sector

In concrete curing systems, asphalt production plants and building material kilns, temperature control is of critical importance. Where high-temperature hot water is required, Dual Fuel Burner solutions are widely used together with a high-temperature hot water boiler.

Dual Fuel Burner Food Industry

Dual Fuel Burner technologies provide an appropriate solution for processes requiring constant and controlled temperature in sterilization, pasteurization and cooking lines. Fuel changeover flexibility offers an important advantage in controlling energy costs.

Dual Fuel Burner Chemical and Petrochemical Industry

Reactor heating systems and pressurized process lines require highly accurate temperature control. Therefore, efficiency-enhancing heat exchanger solutions are also preferred in boiler systems used in the chemical industry. In particular, plate heat exchangers and shell-and-tube heat exchangers are integrated into Dual Fuel Burner systems in heat recovery processes.

Dual Fuel Burner Performance and Efficiency

In performance analyses, combustion efficiency, flue gas temperature, oxygen percentage and NOx/CO emissions are generally taken as reference parameters. As separate combustion optimization is performed for each fuel type in dual-fuel systems, performance values can be evaluated over a wide range.

- Combustion efficiencies in the range of 88%–94% are achievable.

- Low-NOx designs improve compliance with environmental regulations.

- Flue gas temperature is minimized to increase heat recovery.

Dual Fuel Burner Maintenance and Operating Requirements

Regular maintenance is essential for Dual Fuel Burners to operate with high efficiency and long service life.

- Cleaning of nozzles and control of atomization quality

- Replacement of fuel filters

- Recalibration of fan and air-damper settings

- Testing of flame detection sensors

Dual Fuel Burner Conclusion and Overall Assessment

Dual Fuel Burner systems provide a strategic advantage for industrial plants in terms of energy security, efficiency and operational continuity. Thanks to fuel flexibility, operating costs are optimized while compliance with environmental regulations is facilitated. Advanced modulation control, high combustion efficiency and low emission values make these systems an indispensable part of modern industrial heating infrastructure.

For this reason, Dual Fuel Burner technologies are considered an appropriate engineering investment for all facilities that prioritize energy supply security, want to keep their costs under control and aim for high efficiency.

Русский

Русский Türkçe

Türkçe