Follow Us on Social Media!

You can follow our latest engineering solutions and updates on FBR Gas Low NoX FGR Burner technology instantly on our LinkedIn page.

For technical content, product presentations and in-depth explanations, don’t forget to visit our YouTube channel.

To quickly access our field images, application examples and corporate posts, follow us on Instagram.

We also invite you to our Facebook page to join our community and stay informed about our announcements.

What Is an FBR Gas Low NoX FGR Burner?

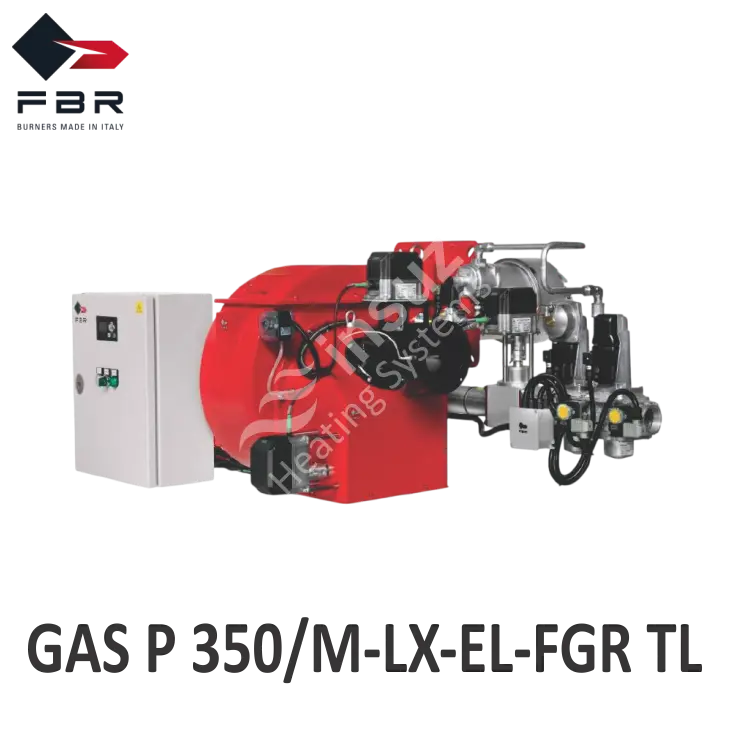

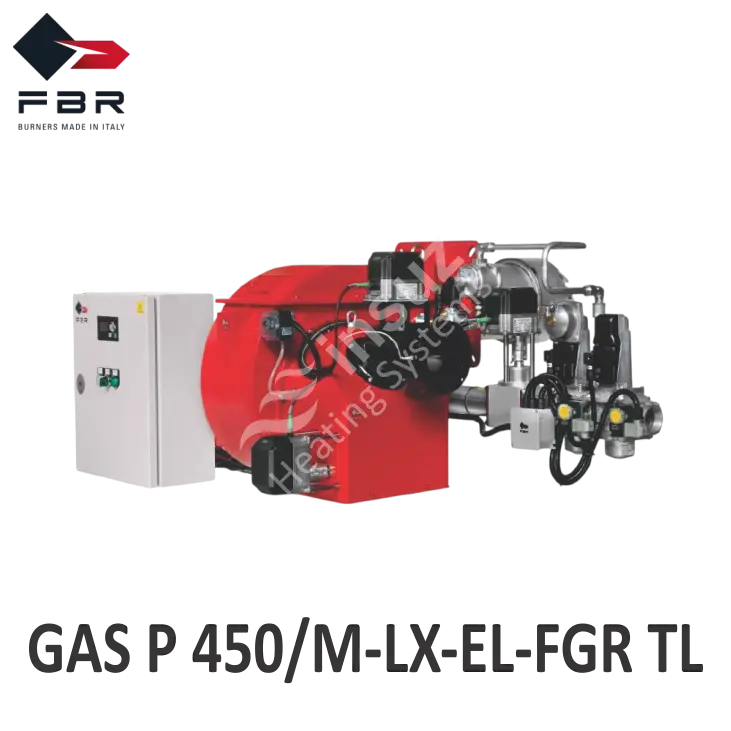

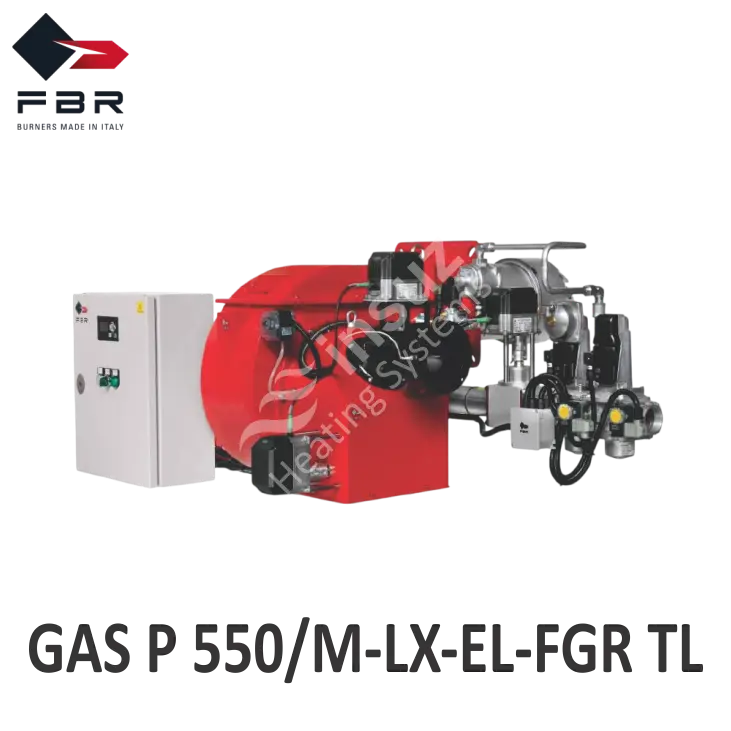

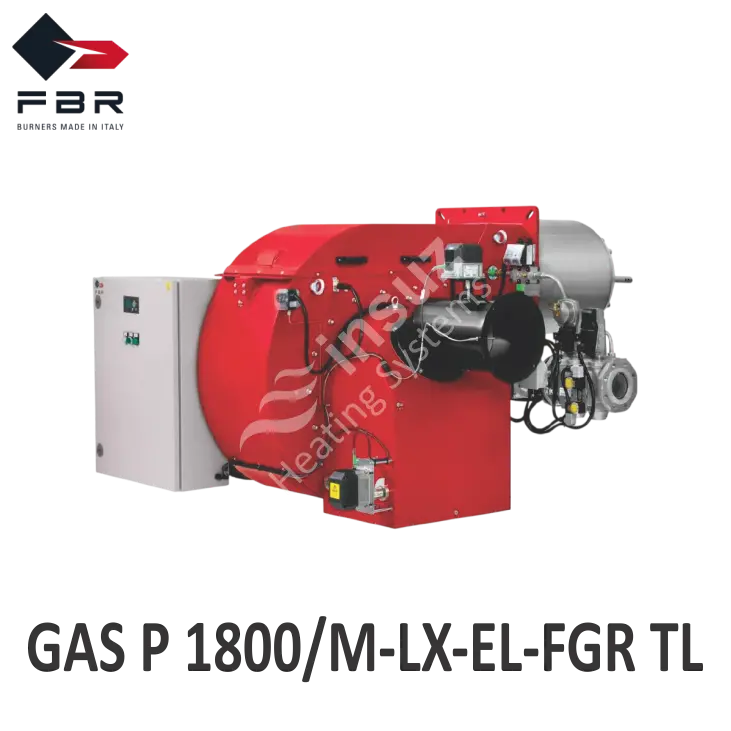

The FBR Gas Low NoX FGR Burner is an advanced burner type developed for modern industrial combustion systems to increase energy efficiency, minimize emission values and support sustainable production processes. Limiting NOx formation is critical in terms of both compliance with environmental regulations and reducing operating costs. In this context, the FGR (Flue Gas Recirculation) system is one of the most effective engineering solutions for achieving low NOx performance, as it directly influences the combustion process both thermodynamically and chemically.

FBR Gas Low NoX FGR Burner – Basic Operating Principle of the FGR System

In the FGR system, a certain percentage of the high-temperature flue gas generated during combustion is recirculated in a controlled way back into the combustion zone. Through this process:

- The oxygen concentration of the combustion air is reduced.

- The flame zone temperature is significantly decreased.

- Thermal NOx formation mechanisms are suppressed.

- A more stable and controllable combustion is achieved.

This technical approach provides high performance especially in low NOx boiler and industrial process applications. Compared to conventional excess air control methods, the FGR method is both more effective and optimizes thermal load distribution within the system.

FBR Gas Low NoX FGR Burner – Importance of the FGR System

The main reason why FGR technology has become widespread in modern burners is that most NOx formation is directly related to flame temperature. Thermal NOx increases rapidly at temperatures above 1300–1500°C. When FGR is activated, the inert components in the flue gas (especially CO₂ and H₂O) act as heat absorbers in the combustion area, reducing core flame temperature. As a result:

- NOx formation can be reduced by 50–80%.

- Combustion becomes more homogeneous and controllable.

- Flame length is regulated and local temperature spikes are prevented.

- Fuel consumption is optimised.

This is a critical engineering advantage for compliance with environmental regulations especially in high-capacity steam boiler and hot water boiler applications.

FBR Gas Low NoX FGR Burner – Technical Advantages of the FGR System

The advantages of FGR in terms of burner performance are quite extensive from an engineering perspective. The following technical benefits are the main reasons why FGR burners are preferred in industry:

FBR Gas Low NoX FGR Burner – Low Emission Advantage

Thanks to the inertisation effect provided by FGR, NOx formation is significantly reduced. This is essential for compliance with strict emission regulations set by institutions such as the European Union and the EPA.

FBR Gas Low NoX FGR Burner – Increased Thermal Efficiency

Bringing the combustion process under better control allows the fuel–air mixture ratio to be maintained at an optimum level. As a result:

- Fuel consumption decreases,

- The flame structure becomes more stable,

- A more homogeneous energy distribution is achieved on boiler heat transfer surfaces.

FBR Gas Low NoX FGR Burner – Longer Equipment Life

Lower flame temperature translates into reduced thermal stress on boiler surfaces. This in turn:

- Slows down corrosion,

- Reduces the risk of deformation on heat exchanger surfaces,

- Minimizes long-term maintenance and operating costs.

FBR Gas Low NoX FGR Burner – Wide Modulation Range

Burners with FGR can ensure stable combustion even at low loads in harmony with modern control systems. This feature is particularly important for process stability in integrations with plate heat exchangers and shell and tube heat exchangers.

Application Areas of the FBR Gas Low NoX FGR Burner

FBR Gas Low NoX FGR Burner in the Automotive Industry

The automotive industry requires low-emission and highly precise heating systems for heat treatment, paint lines and surface processes. FGR burners ensure compliance with environmental standards in these processes.

FBR Gas Low NoX FGR Burner in the Energy Sector

Low NOx levels are mandatory in energy facilities where steam and hot water production is intensive. FGR systems offer optimum performance in both high-capacity boilers and auxiliary firing systems.

FBR Gas Low NoX FGR Burner in the Construction Sector

Stable and controlled combustion is required for heating, asphalt production and drying processes. FGR reduces combustion temperature to create safe and low-emission operating conditions.

FBR Gas Low NoX FGR Burner in the Chemical and Petrochemical Industries

Precise temperature control is critical for reactor feed heaters, process boilers and thermal oxidisers. FGR provides a suitable combustion environment for the stability of chemical reactions.

FBR Gas Low NoX FGR Burner in the Food Industry

Homogeneous heat distribution and low emissions are key factors in hygienic processes. FGR burners meet these requirements with high energy efficiency.

FBR Gas Low NoX FGR Burner – Design and Engineering Approaches

In burners integrated with FGR, engineering design requires careful optimisation of flow analyses, combustion chemistry and thermal distribution calculations. The burner structure typically includes:

- Venturi-type air–gas mixing nozzles,

- Controlled bypass channels for recirculated flue gas,

- Servo-driven dampers providing wide-band modulation,

- High-precision oxygen and temperature sensors,

- PID-based combustion control units

These components working together make it possible to maintain low NOx levels consistently with an FBR Gas Low NoX FGR Burner.

Importance of the FBR Gas Low NoX FGR Burner

The FBR Gas Low NoX FGR Burner is one of the most advanced solutions in modern industrial combustion systems in terms of environmental sustainability, energy efficiency and process reliability. Thanks to the thermal and chemical advantages provided by FGR technology, NOx emissions can be significantly reduced. In addition, the thermal load on the boiler and plant equipment is reduced, extending system life and lowering operating costs.

For these reasons, FGR-supported burners stand out as one of the most accurate engineering choices for high-performance high temperature hot water boilers and heavy-duty process plants.

Русский

Русский Türkçe

Türkçe