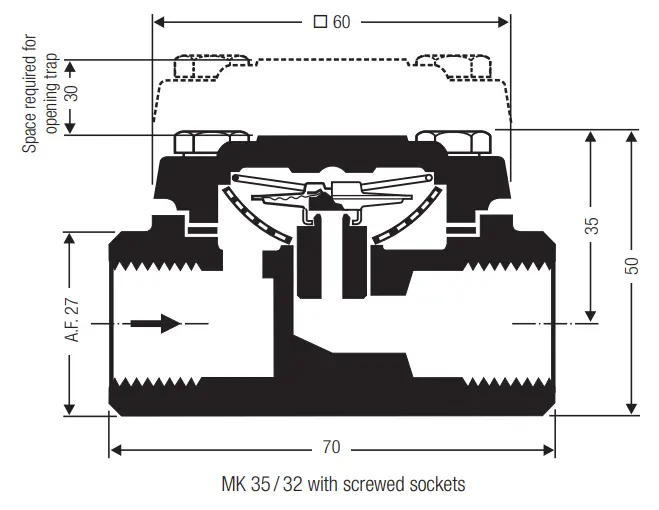

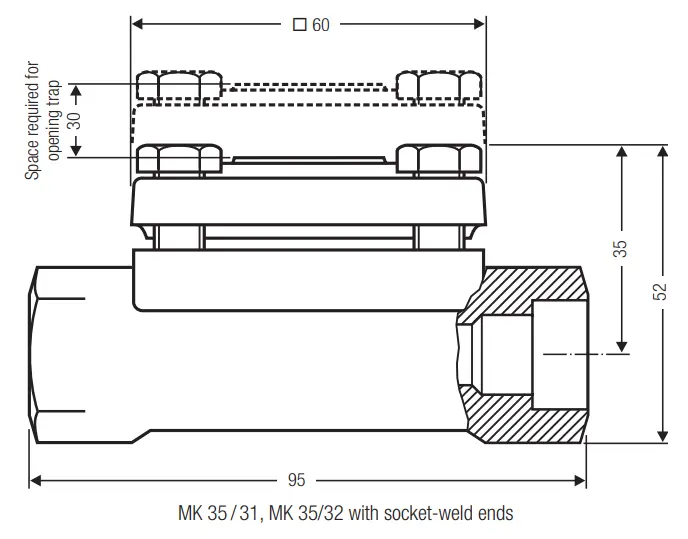

GESTRA MK 35-31 / MK 35-32 Thermodynamic Steam Traps

GESTRA MK35‑31 & MK35‑32 Thermostatic Steam Traps

GESTRA MK35‑31 and MK35‑32 are compact, durable, and precision-engineered thermostatic steam traps designed for efficient condensate discharge in steam systems. Equipped with a stainless steel membrane regulator, these traps are ideal for applications such as steam lines, heat exchangers, and condensate collection systems.

Technical Specifications

Operating Principle: Thermostatic / Thermodynamic

Pressure Rating: PN 25

Sizes: DN 10 – DN 15 (⅜″ – ½″)

Connection Types:

MK35‑31: Tandem seat, threaded

MK35‑32: Single seat, flanged

Integrated strainer and non-return valve

Asbestos-free gasket (graphite/CrNi)

360° universal installation

Optional regulator capsules:

“N” type: Minimal subcooling (~10 K)

“U” type: Extended subcooling (~30 K), ideal for condensate recovery

Working Principle

At system start-up, the trap is fully open, allowing cold condensate and air to discharge rapidly. As the temperature rises and approaches saturation, the stainless steel membrane bends, moving the nozzle toward the closed position. The trap then reopens once the condensate temperature drops, enabling controlled discharge according to system demand.

Typical Applications

Steam distribution lines

Steam tracing systems

Heat exchangers

Process vessels

Equipment requiring fast and efficient condensate removal

Key Benefits

High resistance to pressure and temperature fluctuations

Waterhammer-resistant membrane structure

Compact, maintenance-friendly design

Precise opening/closing action

Optional undercooling for energy efficiency.

Русский

Русский Türkçe

Türkçe