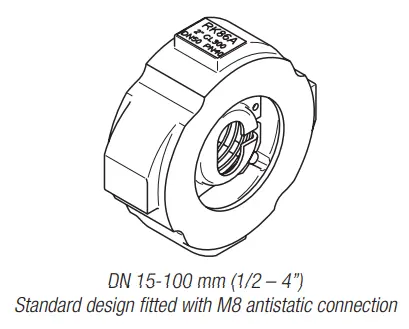

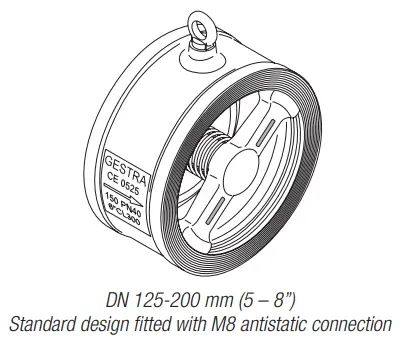

GESTRA RK 86 Series Disc-Type Check Valves

The GESTRA RK 86 Series disc check valves offer compact, high-performance solutions for preventing reverse flow in critical applications. With low pressure drop, fast-response opening and closing, and corrosion-resistant stainless steel construction, they are a trusted choice in numerous industrial systems.

Typical application areas include:

Steam pipelines and condensate return systems

Hot water networks in HVAC and utility systems

Industrial process lines handling clean or slightly aggressive fluids

Thermal oil and heat transfer systems

Power plants and energy centers

Chemical and petrochemical installations

Pump discharge and bypass lines

District heating and cooling networks

Compressed air and inert gas pipelines

Vacuum systems (RKE 86 only, as end-of-line check valve)

Their compact wafer design allows for easy installation in both horizontal and vertical pipe runs, making them ideal for space-constrained environments and retrofit projects.

By supporting operational safety and energy efficiency, the GESTRA RK 86 Series has become an essential component in modern industrial plants.

Key Benefits of GESTRA RK 86 Series Check Valves

🔩 Compact wafer-type design

Space-saving construction enables easy installation between flanges in tight or crowded piping systems.

🔄 Multi-position installation

Spring-loaded models allow for both horizontal and vertical mounting, offering high flexibility during system design and maintenance.

🚫 Effective backflow prevention

Ensures unidirectional flow of steam, liquids, or gases, protecting equipment from pressure surges and reverse flow damage.

💨 Low pressure loss and rapid response

Optimized disc geometry and spring mechanism enable fast opening and closing with minimal flow resistance.

🛡️ Corrosion-resistant stainless steel body

Ideal for aggressive or wet environments, ensuring long-term durability and reduced maintenance needs.

🔧 Self-centering body design

Facilitates precise alignment during installation, reducing installation time and risk of misassembly.

🔒 Leak-tight shut-off performance

High sealing integrity even under varying pressures and temperatures, increasing system reliability.

📏 Wide pressure and size range

Available in DN 15–200 and PN 10–40 / ASME Class 125–300 to suit diverse system requirements.

✅ RKE 86 suitable as end-of-line valve

Certified for use as a vacuum breaker in specific applications (not for safety relief).

Русский

Русский Türkçe

Türkçe