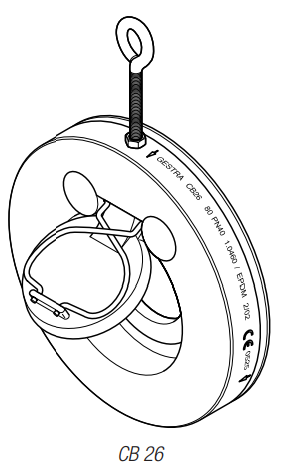

gESTRA CB 24 S - CB26 - CB26A Series Swing Type Check Valves

GESTRA CB 24 S Swing Type Check Valves

GESTRA CB 24S for flanges PN 6/10/16, DN 50 to 300

GESTRA CB 26 for flanges PN 6/10/16/25/40, DN 50 to 300

GESTRA CB 26A for flanges PN 6/10/16/25/40, DN 50 to 300

Description

The GESTRA CB 24 S, CB 26, and CB 26 A models are wafer-type swing check valves (with a flap design) in accordance with EN 558-1, series 96.

Their short face-to-face dimensions and low weight provide advantages in terms of transport, storage, and installation.

The CB 24 S model is designed for installation between flanges that comply with the following standards:

-

EN 1092 PN 6 / PN 10 / PN 16

-

ASME B16.1 Class 125 FF and ASME B16.5 Class 150 RF

This model is equipped as standard with a soft NBR sealing.

The CB 26 and CB 26A models are designed for installation between flanges that comply with the following standards:

-

EN 1092 PN 6 / 10 / 16 / 25 / 40

-

ASME B16.1 Class 125 FF and ASME B16.5 Class 150 / 300 RF

These models are equipped as standard with a soft EPDM sealing.

All models can be installed in horizontal or vertical pipelines.

When installing in vertical pipes, the flow direction must be from bottom to top.

Русский

Русский Türkçe

Türkçe